– 45 –

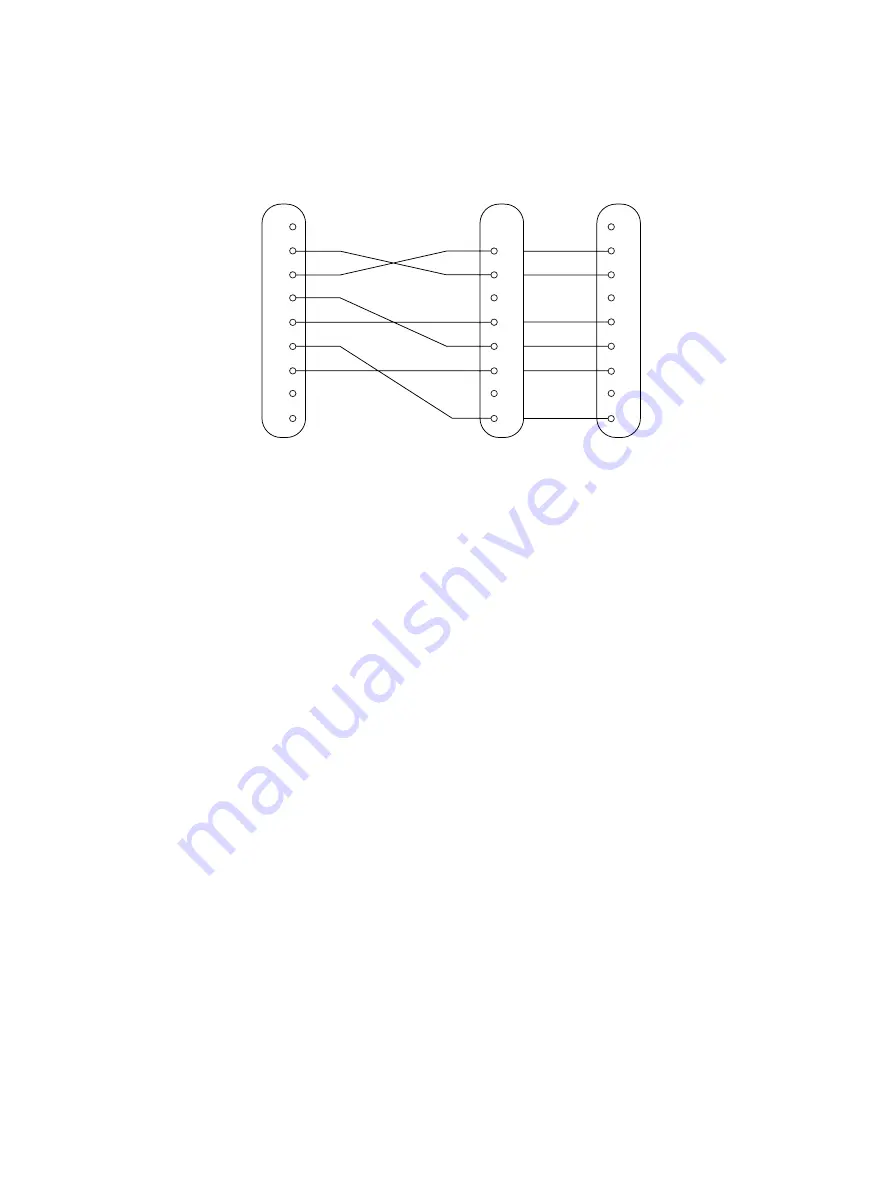

11-1-3. Cable Connections

The followings are a recommended interface cable connections.

Note:

Use shielded wire less than 3 m in length.

11-2. USB Interface

11-2-1. USB Function

1.

General Specification:

Conforms to USB 2.0 Specifications

2.

Communication Speed: USB Full Speed Mode (12 Mbps)

3.

Communication Method: USB Bulk Transmission Mode

4.

Power Specifications:

USB Self-power Function

11-2-2. Connector

• USB Up-Stream Port Connector (USB Type-B)

1

1

2

3

4

5

6

2

3

7

5

8

6

1

4

NC

RXD

TXD

DTR

DSR

RTS

8

9

7

SG

CTS

NC

Printer side

(D-sub 9 pin)

Host side

3

2

4

7

5

6

8

20

RXD

FG

TXD

RTS

SG

CTS

DSR

DCD

DTR

25 pin

9 pin