4. FEATURES AND APPLICATIONS

1)

Use CAD optimized design with artistic looking.

2)

The fan misting system adoptsthe centrifugal atomization optimized design, without

nozzle and water filtration, reasonable structure, easy maintenance.

3)

Fan surface is epoxy resin coated,anti-rust and durable.The fan has water proof

electrical design, safety,with tank cart, easy to move.

4)

Misting and air supply driven by different motors, motors use high quality rolling

bearings, with stable performance, low temperature rise, long life, low noise, strong

overload.

5)

Misting volume adjustable, pumps take full insulation enclosed protective structure

for safe operation.

6)

The fan with the function of oscillation and adjustable angle. easy to use, suitable for

factories, residential areas, shopping malls, sports grounds cooling, dedusting, odor

removal, and also can be used in livestock farms, greenhouses, mushroom farms and

special places.

5. PRODUCT BENEFITS

1) Centrifugal misting system means there is no clogged nozzles and no need to use

filtered water.

2) It is equipped with a UV lamp, located in the tank, to sterilise water and prevent the

formation of bacteria (such as legionella, for instance) and mould.

3) Fan surface is epoxy resin coated, anti-rust and durable.

4) The fan electrical components are designed to be waterproof.

5) Safe to use, with tank cart, easy to move.

6) Air supplying and misting functions are driven by different motors. Motors adopt

high quality ball bearings, with advantages of stable, low temperature-rise, long

service life, low noise, and strong overloading ability.

7) Misting volume adjustable, the pump adopts full insulation enclosed protective

structure for safe operation.

8) It has three adjustable speed and the function of left and right oscillation, easy to

use.

9) Designed for cooling large areas such as patios, factories, manufacturing facilities,

garages, athletic fields, greenhouses, live stock breeding farms and more.

6. OPERATION INSTRUCTIONS

1)

Use the fan under the voltage and frequency shown on the rating label, do not use

in corrosive environment.

2)

Do not install this machine in places where the altitude is higher than 1,000 meters

or temperature is over 40

℃

.

3)

When socket is used in power supply, the socket should meet the IEC335-1 standard;

when power liner is from direct power supply, a polarity switch should be installed

with contact gap not less than 3mm on the fixation wiring.

4)

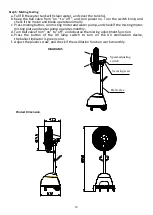

Oscillating angle adjustment: Loosen the oscillation screw and move it to the desired

position (the more outward the more bigger oscillation angle), tighten this oscillation

screw after adjustment.

5)

Tilting angle adjustment: Loosen the fixing nut and move the motor to the desired

position and tighten this fixing nut.

6

Summary of Contents for FRE326N

Page 1: ...STAR BRUMA MISTING FAN NEW WITH UV DEVICE FOR WATER STERILIZATION ...

Page 12: ...12 ...

Page 13: ...13 ...