Service Manual: E-TR and E-TRi

11

DAILY

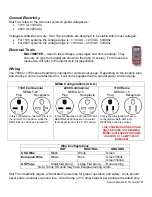

Clean

•

Use a 5:1 dilution ratio (5 parts water to1 part Simple Green

, Formula 409

,

Fantastic

,or the like).

+

=

(5 parts water)

(1 part cleaner)

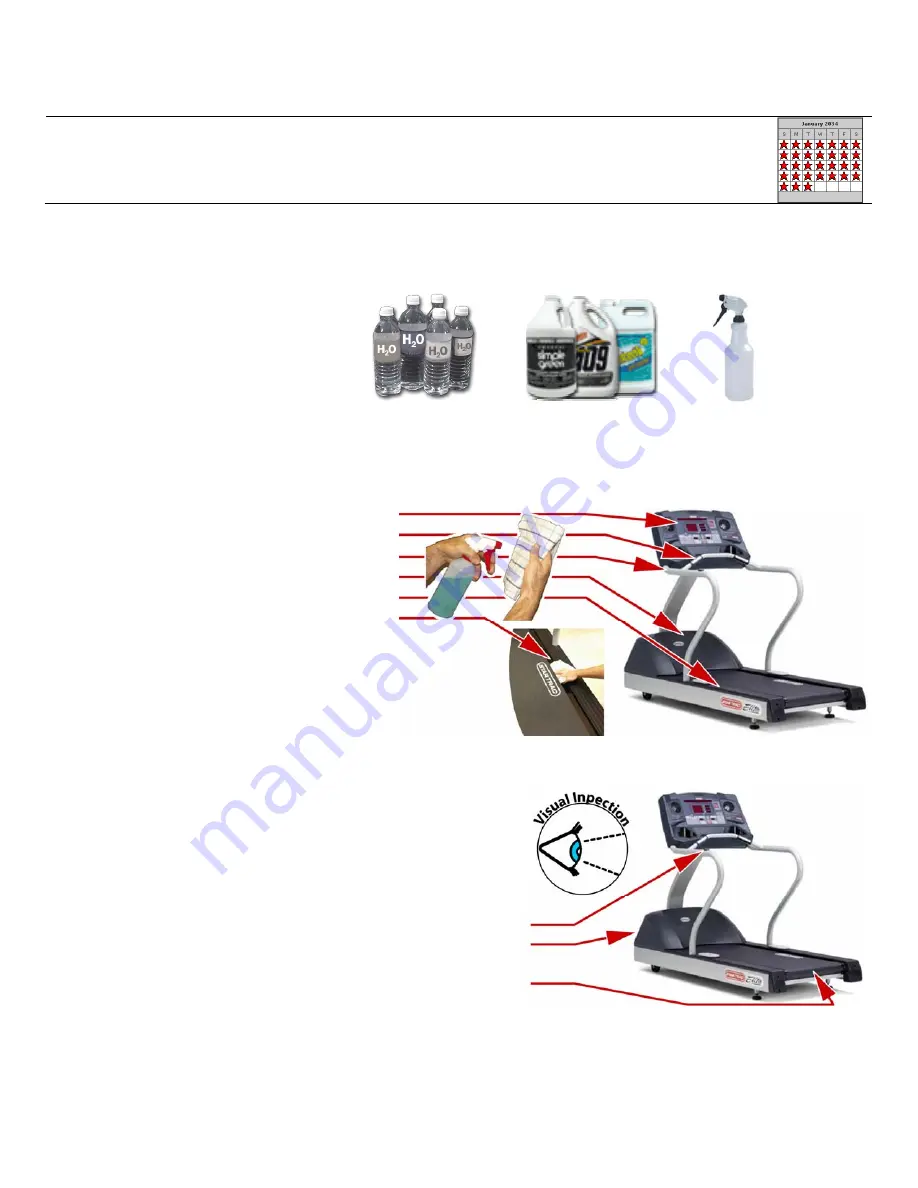

Apply cleaning solution to a clean cloth then wipe the following areas (Do not spray

directly onto surfaces):

o

Display

(Keypad)

o

Heart Rate Grips

o

Handrails

o

Shroud

o

Side Bed Covers

o

Under Belt Edge

Inspect

•

Inspect running belt for proper alignment

(see Running Belt section for adjustment)

•

Inspect for wear and tear on exterior parts

to include:

o

Side stop switch for function

o

Shroud, housing and other

plastics for damage

o

Running belt seam for tears or

splits

Summary of Contents for Pro Tread AC 7600

Page 47: ...Service Manual E TR and E TRi 45 SOFTWARE MCB...

Page 59: ...Service Manual E TR and E TRi 57 DFR Code 1000000 100000 and 10000...

Page 60: ...Service Manual Treadmills E Series P Series 58 DFR Code 4000...

Page 61: ...Service Manual Treadmills E Series P Series 59 DFR Code 1000...

Page 65: ...Service Manual Treadmills E Series P Series 63 DFR Remaining Codes...

Page 67: ...Service Manual AC Pro Tread 7600 7700 65 This page intentionally left blank...