PARTS LIST

September 16, 2015, Rev. F

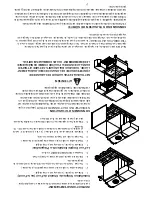

Ultra-Max Electric Conveyor Oven

UM1833A/1850A-208/240V - Control Box , AC Motor

IMPORTANT: WHEN ORDERING, SPECIFY VOLTAGE OR TYPE GAS DESIRED

PAGE

INCLUDE MODEL AND SERIAL NUMBER

OF

Some items are included for illustrative purposes only and in certain instances may not be available.

Number

Per

Unit

Description and Model Designation

MODEL

Part

Number

Key

Number

1

1

2

4

3

2C-200201

4

4

1

5

18

6

1

7

1

8

1

9

2

10

1

11

1

12

1

13

1

14

2

4

UM1833A208/3

15

11

16

2C-200262

20

17

34

18

40

19

1

20

1

21

4

22

1

23

G9-EC0135

1

24

2E-Z

22343

1

25

2

26

13

27

2E-

Z22343

1

28

2

29

2

30

G9-

EC0136

1

31

1

32

1

33

1

34

1

35

2

36

1

NI

2

NI

1

NI

2

NI

2M-Z13287

1

NI

2M-Z13289

1

UM1833A208/3

NI

1

SWITCH-LIGHTED

SPACER .257X.75X.25 NYLON

NUT 6-32 HEX LOCK SS

KIT,OVEN CNTRL-PRGM+REPLMNT

SCREW, 8-32 X 3/8 THP SS

THERMOSTAT, 160F UM1854

BUSHING HEYCO #SR-9

HIGH TEMP LIMIT UM1854

SCREW M4X5 PHP STL NP

CONTROL BOX LID

CONTROL BOX DOOR ASSY

TRANSFORMER, UM1833

THERMOCOUPLE ASSEMBLY

HALF CLAMP .188 D STL ZP

HALF CLAMP .188 D STL ZP

SCREW 8-32X1/2 RHP STL NP

NUT WELD 1/4-20 SS

WASHER 1/4 SPLIT SS

BOLT 1/4-20 X .75 HEX SS

DRIVE COG

COUPLING, SPRING LOADED

SCREW 10-24X1/2 SS THP

GEARMOTOR MOUNT

GEAR MOTOR

SPEED CONTROL-GEAR MOTOR

SCREW 8-32X3/4 RHP STL NP

WASHER, SS #8 INT

OCTAL SOCKET BASE

TERMINAL BLOCK 1/4 P.O.

FUSE, 5A - CLASS G

CONTROLS MOUNT

RUN CAPACITOR

THERMOSTAT, 140F UM1854

FUSEHOLDER, CLASS G

DRAFT TUBE HOSE UM-1854

SCREW #8-3/8 AB HEXW STL

SWITCH, DIFF. PRESS.

CONTACTOR, 40 AMP, 24VAC

CORD SET 208V, 50A CONTACTOR,

3 POLE

DIAGRAM UME 1PHASE DIAGRAM

UME 3PHASE DELTA GRAPHIC,

CONTROL LABEL

1

1

Manufactured After 10/2010

Summary of Contents for Holman Ultra-Max UM1833A

Page 21: ......