11

OPERATION

General

The suggested time and temperature chart (below) is provided as a guide for the products listed only.

If different temperature settings are to be used, select one side of the griddle and operate at the lowest

temperature. Adjoining sections should be set at progressively higher temperatures. Do not try to

operate the end sections hot and the center sections cool.

ALWAYS KEEP THE AREA NEAR THE APPLIANCE FREE FROM

COMBUSTIBLE MATERIALS.

KEEP FLOOR IN FRONT OF EQUIPMENT CLEAN AND DRY. IF

SPILLS OCCUR, CLEAN IMMEDIATELY, TO AVOID THE DANGER OF

SLIPS OR FALLS.

Operations

An understanding of how the griddle sections are controlled will be a valuable aid in loading product on

your unit.

Each 12-inch section of your griddle is independently controlled by a temperature controller. The

temperature control sensor is mounted in the center of each cooking section under the griddle plate.

If the product is loaded directly over the temperature sensor, that section will turn on and the burner will

heat the entire cooking section. If the product is loaded to the side, front or back of the temperature

sensor, the thermostat will react to the temperature change much slower.

During slow periods with minimal loads, do not load directly over the thermostat sensors as this will

unnecessarily turn the burners on and overheat the remainder of the section not being utilized.

Turn the product and continue cooking

until it has reached its desired degree

of doneness.

Remove the product from the griddle.

When reloading the griddle,

fi

rst

use the griddle surface on which a

previous load was not placed. This

will help insure the proper griddle

temperature.

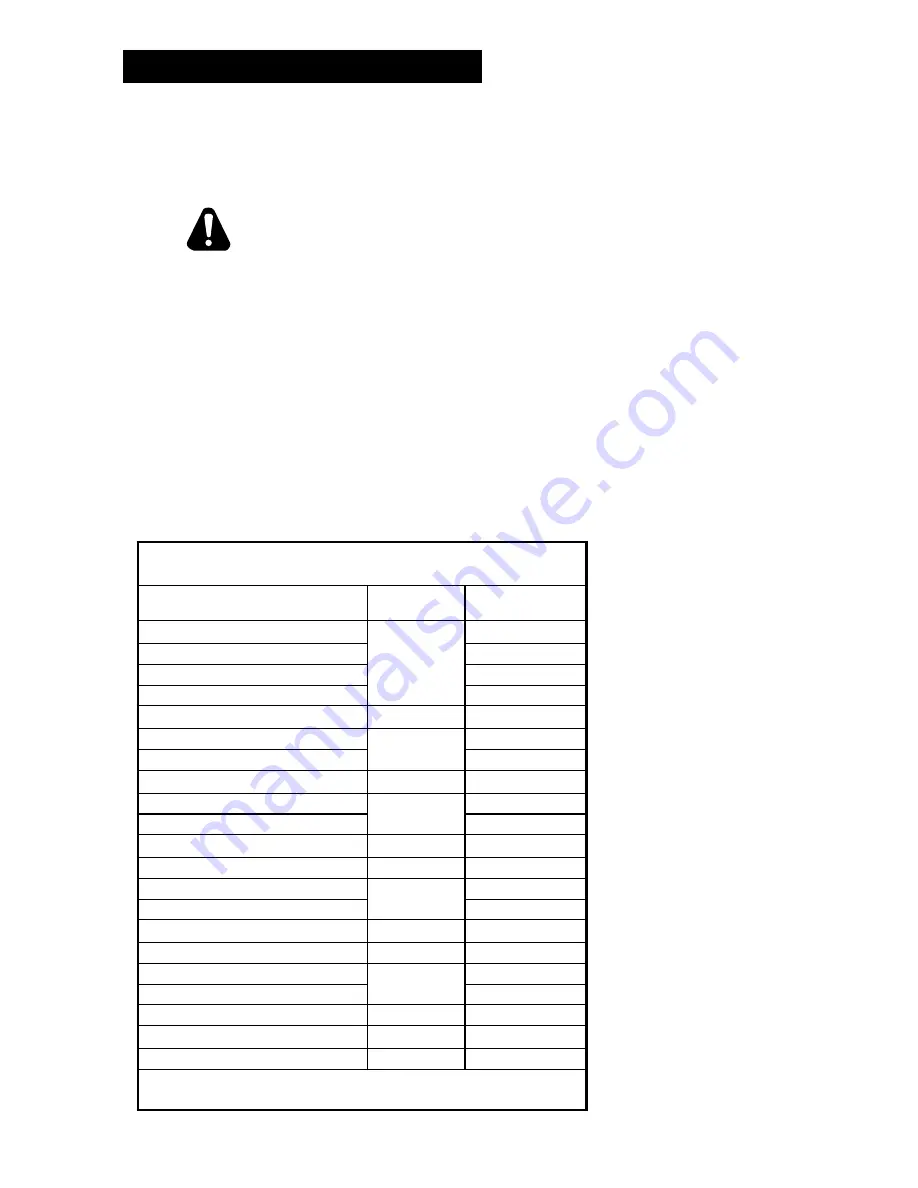

SUGGESTED TIMES AND TEMPERATURES

PRODUCTS

TEMPERATURE

F / C

TIME (MIN)

HAMBURGER

350°F / 176°C

2 patties per LB

6 to 8

4 patties per LB

4 to 6

6 patties per LB

3 to 4

STEAKS

1/2 to 3/4 inch thick, cooked medium

375°F / 190°C

5 to 7

3/4 to 1 inch thick, cooked medium

8 to 10

Lamb Chops

350°F / 176°C

6 to 8

Pork Chops

6 to 8

Salmon

350°F / 176°C

6 to 8

Halibut

325°F / 162°C

6 to 8

Snapper

6 to 8

Hash Brown Potatoes

375°F / 190°C

3 to 4

Bacon

350°F / 176°C

3 to 4

Sausage Links or Patties

3 to 4

Ham (Pre-cooked)

375°F / 190°C

2

Eggs

275°F / 135°C

2 to 4

Note: The times and temperatures in this chart are intended as a general guide and starting point.

Your actual times and temperatures may vary from this chart.

CAUTION

Summary of Contents for Lang 124S

Page 17: ...17...