9

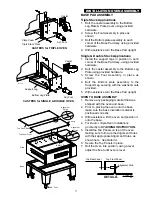

PRESSURE READING

TEST NIPPLE

IL1191

SET-SCREW

GAS PRESSURE

ADJUSTMENT SCREW

IS UNDER CAP

OVEN MANIFOLD PRESSURE REGULATION

Each oven has been adjusted at the factory to operate with

the gas speci

fi

ed on the nameplate.

Each oven is supplied with a regulator to maintain the proper

gas pressure. The regulator is essential to the proper

operation of the oven and should not be removed or replaced

by another model unless approved by Star Manufacturing.

A pressure reading can be taken at the test nipple provided.

You must back the set-screw one turn for this test, be certain

to re-tighten when you are done. Failure to reset the set-

screw to its original position will create a gas leak once the

unit is back in operation. The reading should be taken while

the oven is heating up & at high

fi

re. The regulator is located

on the bottom of the gas combination valve, just inside the

control box. Adjust gas manifold regulator gas pressure by

removing the cap and adjusting the regulator adjustment

screw to match the pressure listed on the name plate (3.5"

Nat, 4.8" Propane). Clockwise to increase, counterclockwise

to decrease.

Oven Manifold Regulator, w/Set Screw

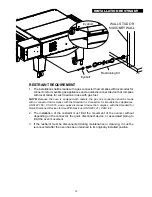

PRESSURE TESTING GAS SUPPLY LINE

During pressure testing note the following:

1. The oven and its individual manual shut-off valve must be disconnected from the gas supply piping

system during any pressure testing of that system at test pressures in excess of 1/2 psig (3.45 kPa).

Turn OFF

main gas shut-off valve or main gas supply line.

2. The oven must be isolated from the gas supply piping system by closing its individual manual shut-

off valve during any pressure testing of the gas supply piping system at test pressures equal to or

less than 1/2 psig (3.45 kPa).

3. If incoming pressure is over 14" water column, a separate regulator for the oven must be installed

before the gas supply to the oven.

To prevent damage to the control valve regulator during the initial turn-on of

gas, it is very important to open the manual shut-off valve very slowly. After the

initial gas turn-on, the manual shut-off valve must remain open except during

pressure testing as outlined in the above steps or when necessary during service

maintenance.

NOTE: The supplied regulator is evaluated for a maximum gas supply pressure of

14" water column (34.5 mBar). The recommended maximum gas supply pressure

is 12" water column (29.9 mBar).

Installation must conform with local codes or, in the absence of local codes, with the National

Fuel Gas Code, NFPA54/ANSI Z223.1 - Latest Edition, the Natural Gas Installation Code

CAN/CGA-B149.1 or the Propane Installation Code CAN/CGA-B149.2 as applicable.

UTILITY INSTALLATION

CAUTION

WARNING

Summary of Contents for Ultra-max UM3240

Page 27: ......