7

INSTALLATION INFORMATION

THE INSTALLATION INSTRUCTIONS CONTAINED HEREIN ARE FOR THE USE OF

QUALIFIED INSTALLATION AND SERVICE PERSONNEL ONLY. INSTALLATION OR

SERVICE BY OTHER THAN QUALIFIED PERSONNEL MAY RESULT IN DAMAGE TO THE

OVEN AND/OR INJURY TO THE OPERATOR.

Quali

fi

ed installation personnel are individuals, a

fi

rm, a corporation, or a company which either

in person or through a representative are engaged in and responsible for:

1. The installation or replacement of gas piping and the connection, installation, repair, or

servicing of equipment.

2. The installation of electrical wiring from the electric meter, main control box, or service outlet

to the electric appliance.

Quali

fi

ed installation personnel must be experienced in such work, familiar with all precautions

required, and have complied with all requirements of state or local authorities having

jurisdiction.

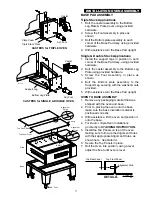

LOCATION

The well-planned and proper placement of your oven will result in long-term operator convenience

and satisfactory performance.

NOTE:

On gas conveyor ovens, routine servicing can usually be accomplished within the limited

movement provided by the gas hose restraint. If the oven needs to be moved further from the

wall, the gas must

fi

rst be turned off and disconnected from the oven before removing the restraint.

Reconnect the restraint after the oven has been returned to its regular position.

It is essential that an adequate air supply to the oven be maintained to provide a suf

fi

cient

fl

ow

of combustion and ventilation air. Follow these guidelines:

1. Place the oven in an area that is free of drafts.

2. Keep the oven area free and clear of all combustibles such as paper, cardboard,

fl

ammable

liquids, and solvents. Oven should only be used on Non-Combustible Floors.

3. Do not place the oven on a curb base or seal to a wall. This will restrict the

fl

ow of air and

prevent proper ventilation to the blower motors. This condition must be corrected to prevent

permanent damage to the oven.

4. On all models, tripping of the blower motor's thermal overload device indicates an excessive

ambient temperature at the back of the oven. This condition must be corrected to avoid

permanent damage to the oven.

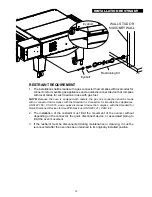

GAS SUPPLY RATING AND SIZING

Calculations for pipe sizing must take into account the maximum usage rate of all other appliances

in the kitchen or one or more of the appliances will suffer from inadequate or dangerous

performance. The 3/4" NPT connection for the oven is generously sized for use in the control

box of the oven. However, unless the oven installation is within 10 feet of the main building gas

supply, the supply must be larger. For each oven, a 3/4" NPT

fl

exible quick connect hose and

full port gas shut-off valve is recommended as a MINIMUM. The main pipe supplying each oven

branch may need to be larger depending on the number of appliances serviced, the number

of elbows in the piping, and the pressure. This should be sized and installed by a professional

familiar with any local codes that may also affect the installation.

ACCESS CONSIDERATIONS

Locating the gas valve(s), quick connect hose(s) and electrical outlet(s) at the control box end

of the oven will allow easier access for any service visits. This improved access should make

any necessary service quicker resulting in less kitchen disruption. It will also allow easier

disconnection of electricity, gas, and restraints for cleaning around and behind the oven.

UTILITY INSTALLATION

Summary of Contents for Ultra-max UM3240

Page 27: ......