10

10. Troubleshooting

When trouble is found, check the following again before consulting your dealer. If none of these is applicable or the the

trouble is not remedied even after action has been taken, a failure of this product is suspected.

Check/Remedy

Cause

Solution

Pilot Lamp does not light.

Power Switch is OFF.

Turn ON the switch.

AC Adapter is not connected correctly.

Check the connection.

Internal Fuse is blown

Contact your dealer.

Motor does not run

Tubing, Motor Cord, AC Adapter is not connected

correctly.

Check the connection.

Air pressure is not given, or not at proper level from the

delivery unit.

Check the air pressure of the delivery system.

Check the ERROR CODE in the Speed Indicator.

Refer to 9. ERROR CODE.

The rotation speed does not rise.

Air pressure is not given, or not at proper level from the

delivery unit.

Check the air pressure of the delivery system.

Air pressure of the delivery unit is lower than the “Lower

limit of the air pressure”.

Do "6. (1) Foot Air Calibration".

It beeps when switch is turned

on.

You are stepping on the Foot Pedal when turning on the

power switch. (Safety function)

Do not press the Foot Pedal, and turn on the

power switch simultaneously.

Light Bulb does not light.

Light Bulb is not connected correctly.

Insert the Light Bulb correctly and firmly. (Refer

to 8. (2) Replacing Bulb)

Light Bulb is burnt-out

Please replace the Bulb. (Refer to 8. (2)

Replacing Bulb)

Motor heats up abnormally

during operation.

Coolant air is not given, or not at proper level from the

delivery unit.

Check the air pressure of the delivery system.

Water leakage

Tubing, Motor Cord is not connected correctly.

Check the connection.

If leak is from Control Box, something is wrong within the

Control Box.

Contact your dealer.

When turned on, the setting

values are different from what

used to be when turned off.

Turned off the motor while rotating.

Turn off after the Motor has stopped.

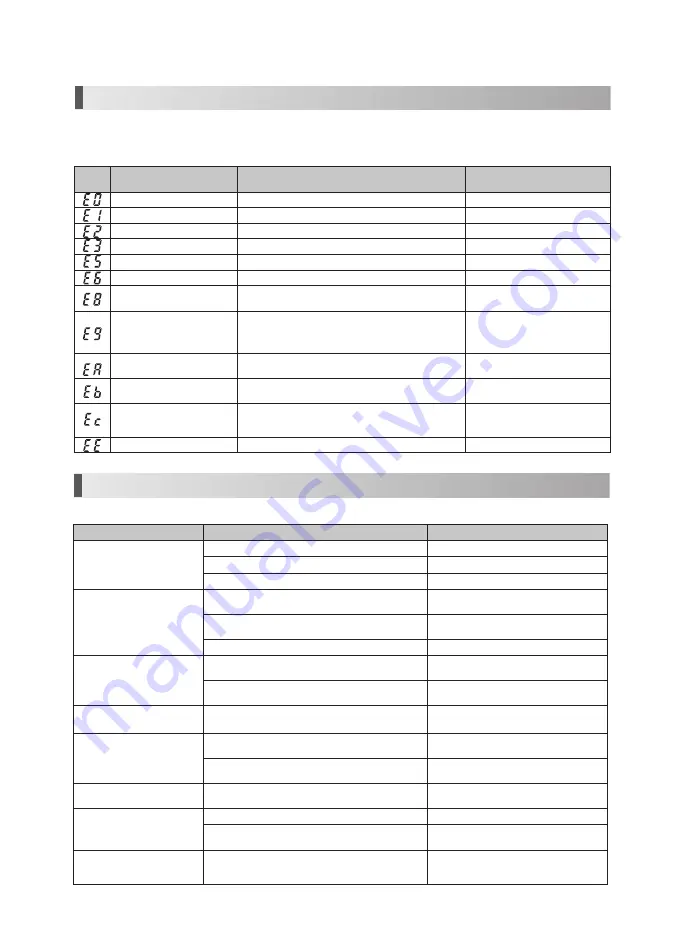

9.

Error Code

Error

Code

Trouble

Cause

Check/Remedy

Overcurrent error. (In circuit)

Detected overcurrent in the circuit.

Contact your dealer.

Overcurrent error. (In software) Detected overcurrent in the software.

Contact your dealer.

Retry Error

Motor stopped by overload, and not able to restart.

Contact your dealer.

ITRIP Error

Faulty Motor or Internal circuit.

Contact your dealer.

Overvoltage Input Error

Overvoltage is given to the Control Box.

Contact your dealer.

Bulb voltage Error

Overvoltage is given (more than 3.7V) from the Internal circuit. Contact your dealer.

Overheat Error

High temperature safe system is functioning, due to long-

time use at a high load.

Allow unit to cool and try again.

Motor Start Error

- Motor didn't reach the preset speed in a prescribed

period of time.

- Break down of a motor cord wire, or internal circuit

malfunction.

Contact your dealer.

Bulb voltage Error

Voltage for the Bulb did not reach the preset level in a

prescribed period of time.

Contact your dealer.

Air Offset Error

Lower than preset " Lower limit of the air pressure"

Displayed by Foot Air Calibration

function. Not a malfunction.

Air Full Scale Error

- Higher than preset "Upper limit of the air pressure".

- Air pressure higher than 0.4MPa (=4.0kgf/cm

2

=56.89psi)

is given.

Displayed by Foot Air Calibration

function. Not a malfunction.

EEPROM Error

Malfunction of the memory for the setting values.

Contact your dealer.

If the motor stops due to an abnormality such as a malfunction, overload, breakage or incorrect usage, the Control Box will

display an error code on the Speed Indicator. If an error code is displayed, turn on the power again and check whether the

same error code is displayed. If the same error code is displayed, take action by referring to the instructions provided in

the "Check/Remedy" column in the following table.