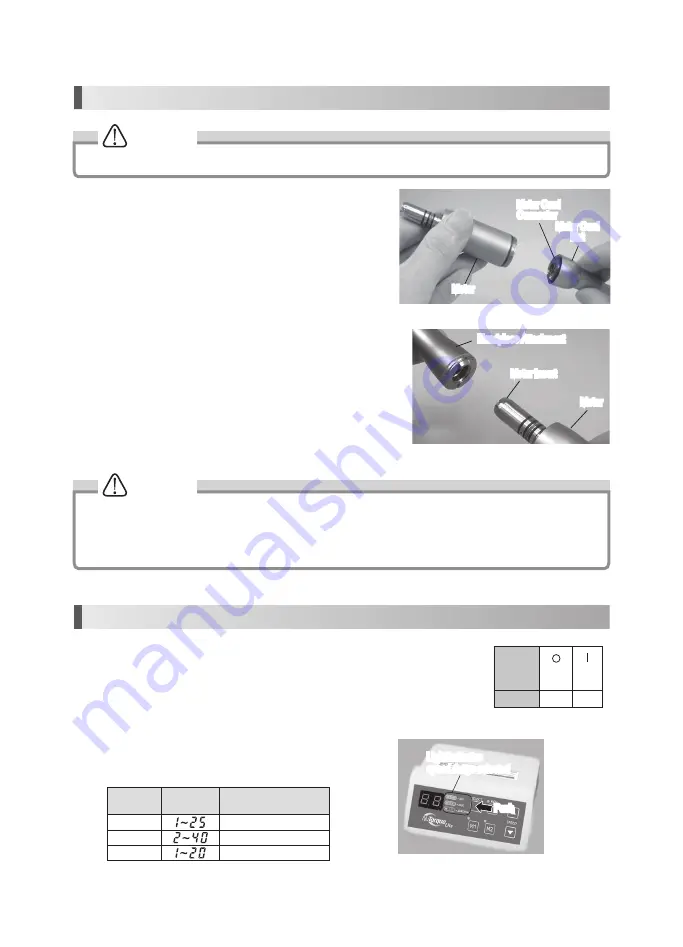

Fig.6

CAUTION

Fig.7

Motor

Motor Cord

Nut

Motor Cord

Connector

Handpiece Attachment

Motor Insert

Motor

CAUTION

(2)

Connecting/disconnecting the motor and the handpiece Attachments

Assemble the Handpiece Attachment by inserting the motor insert into

the E-Type Handpiece Attachment, and turn Attachment until it clicks

and positioning pins are aligned.

Remove the handpiece by pulling the handpiece attachment out from

the motor.

· Care should be taken when using any handpiece attachment which requires lubrication (E-Type Micromotor).

Following lubrication, stand the handpiece attachment vertically until the excess solution drains. Wipe the

handpiece then attach it to the micromotor.

· Do not connect or disconnect the handpiece until the motor has completely stopped.

5. Operation Section

(1) Insert the Power Cord Plug in AC outlet and turn on the Power Switch. When you turn on the

Power Switch, lamps and speed indicator will be illuminated.

(2) Before using this system, make sure to perform Foot Air Calibration function.

(Refer to 6. (1) Foot Air Calibration)

Power

Switch

Symbol

Mark

Function

OFF

ON

(3) Push the Gear Ratio Select Key to indicate the speed of the

attachment you will use. (Fig. 7)

Handpiece

Gear Ratio

Indicator

Speed (min

-1

(rpm))

16:1

100 - 2,500

1:1

2,000 - 40,000

1:5

10,000 - 200,000

Fig.5

4. Handling the Motor

(1) Connecting / disconnecting the motor and the motor cord

To remove the motor cord from the motor, unscrew and detach the

motor cord nut, and gently pull out the motor cord connector.

To connect, align and insert firmly the pins of the connector

carefully into the pin holes of the motor, and fasten the motor cord

nut securely (Fig. 5)

Push

Ensure that the motor has completely stopped before handling the motor.

5

Motor

Motor Cord

Nut

Motor Cord

Connector

Handpiece Attachment

Motor Insert

Motor

Light indicates

speed range selected

Light indicates

speed range selected

Push