16

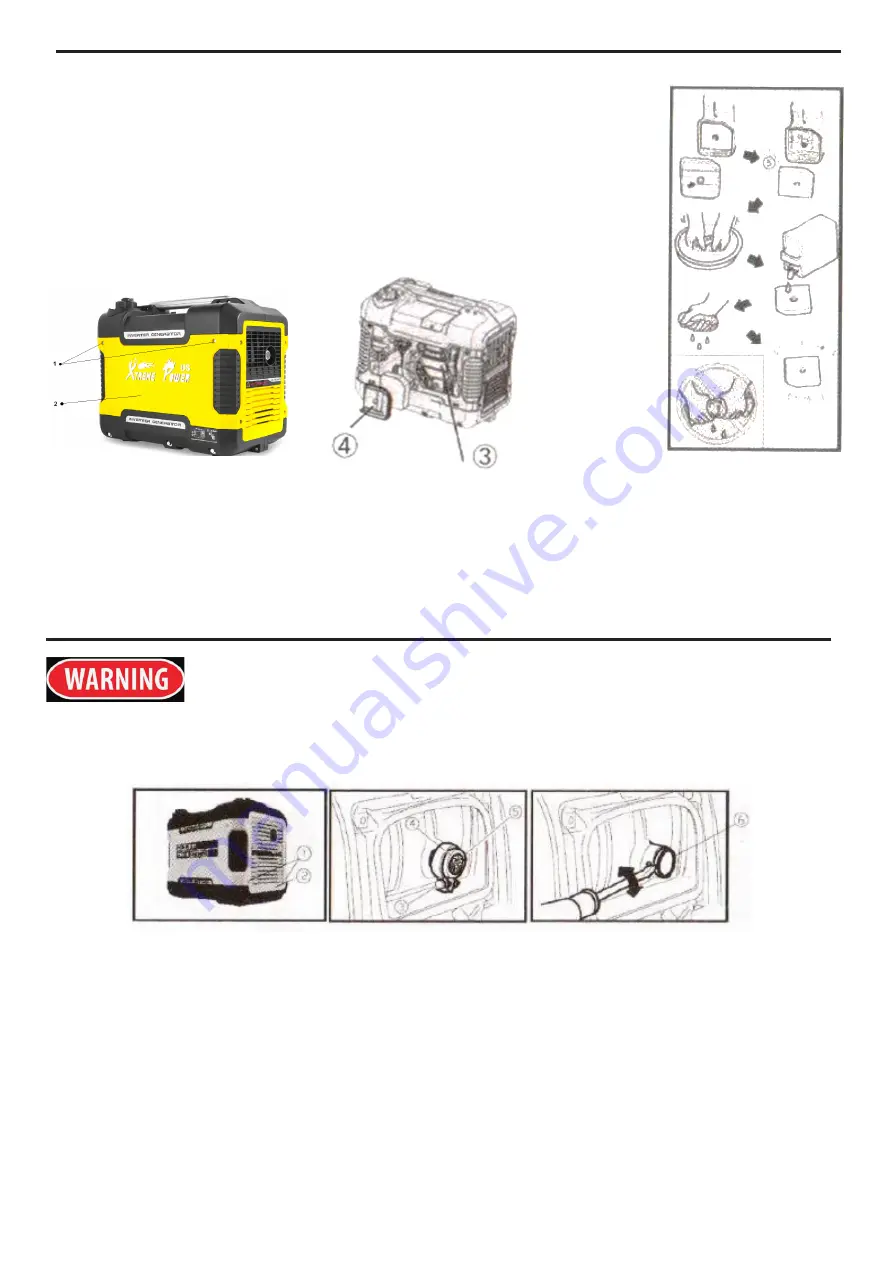

AIR FILTER

1. Remove the screws (1) and then remove the cover (2).

2. Remove the screw (3) and then remove the air filter case cover (4)

3. Remove the foam element, wash it in solvent and dry it.

4. Oil the foam element and squeeze out excess oil. The element should

not be dripping. Do not wring out the foam element when squeezing as

6. Insert the foam element into the filter case. Be sure the element sealing surface matches the air

filter. Never run the engine without the foam element in the correct position.

5. Install the air filter case cover and tighten the screws.

6. Install the over and tighten screws.

MUFFLER SCREEN AND SPARK ARRESTER

THE ENGINE AND MUFFLER WILL BE VERY HOT AFTER THE ENGINE HAS BEEN RUN.

AVOID TOUCHING THE ENGINE AND/OR MUFFLER WHILE STILL HOT. SERIOUS INJURY

CAN OCCUR.

1. Remove the screws (1) and pull outward on the areas of the cover (2)

2. Loosen the bolt (3) then remove the muffler cap (4the muffler screen (5) and

spark arrester (6)

3. Clean the carbon deposits on the muffler screen and spark arrested using a

wire brush.

4. Check the muffler screen and spark arrester, replace if damaged.

5. Install the spark arrester, muffler screen, muffler cap and cover, to be sure to

tighten the screws.

Summary of Contents for 65064

Page 6: ...COMPONENTS AND CONTROLS 5 ...

Page 20: ...TROUBLESHOOTING 19 ...