2.3 Door Switches

The CybaMICRO controller includes a door switch monitoring system to enhance the

overall system safety. There is a door switch fitted to the cardboard chamber top

door, and a separate switch to the plastic chamber top door.

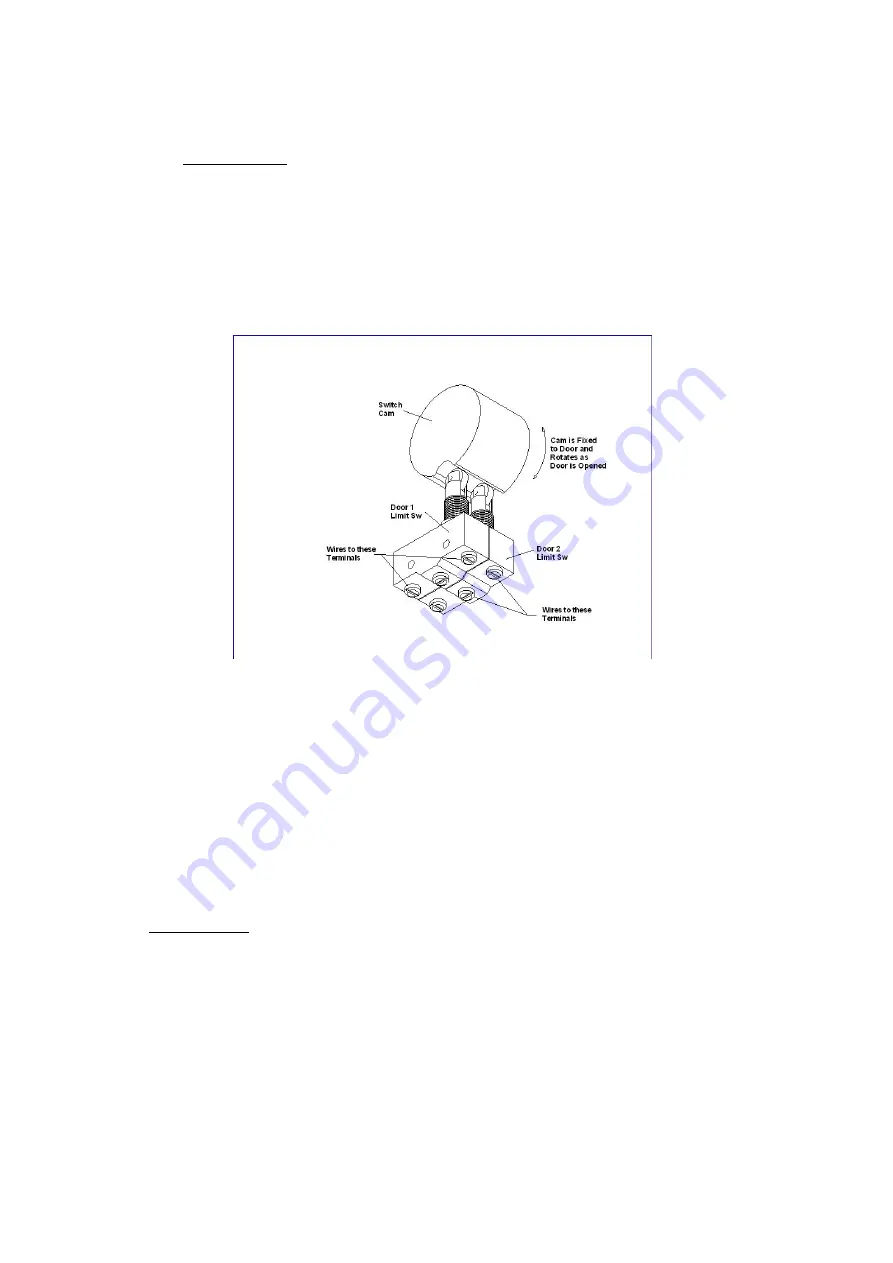

Two separate switches must be used for each door as shown in the figure below. If

one switch were to fail then the operation of the second switch would be sufficient to

indicate the failure in the first switch. The monitoring circuitry will then default to the

safe state, which is the Door Open. The monitoring system will also similarity detect

Fig 2: Door Switch Assembly Example

In this system Door 1 Limit Switch must close its contacts when the door is shut, and

Door 2 Limit Switch must open its contacts when the door is shut. Whenever the door

is changed from open to shut, or shut to open, the contacts in both switches must

change state. That is, when the door is opened Door 1 Limit Switch must open its con-

tacts, and Door 2 Limit Switch must close its contacts.

Any fault in the system will result in Door open being displayed in the system monitor.

The CybaMICRO models may also have an encoded magnetic door switch fitted. The

principle of operation is the same .

2.4 Tilt Switch

The CybaMICRO controller is designed to control a baler with dual hydraulic cylinders

that must remain synchronized in their stroke. Under certain conditions these cylinders

may loose their synchronization, and the tilt switch is fitted to the machine to indicate

this condition and prevent the machine from operating and causing mechanical dam-

age. If the message Tilt Fault appears when the power is switched on, then the cylin-

ders must be re-synchronized before the baler can be operated (call baler manufac-

turer for details).

Page 8