ADJUSTMENTS

Hold Down:

Using the upper thumbscrew on the side of the machine, adjust the hold down for

tensioning. For best results, labels should be pressed firmly against the strip plate.

However, if the labels are held too tightly, they will cause excessive drag on the motor.

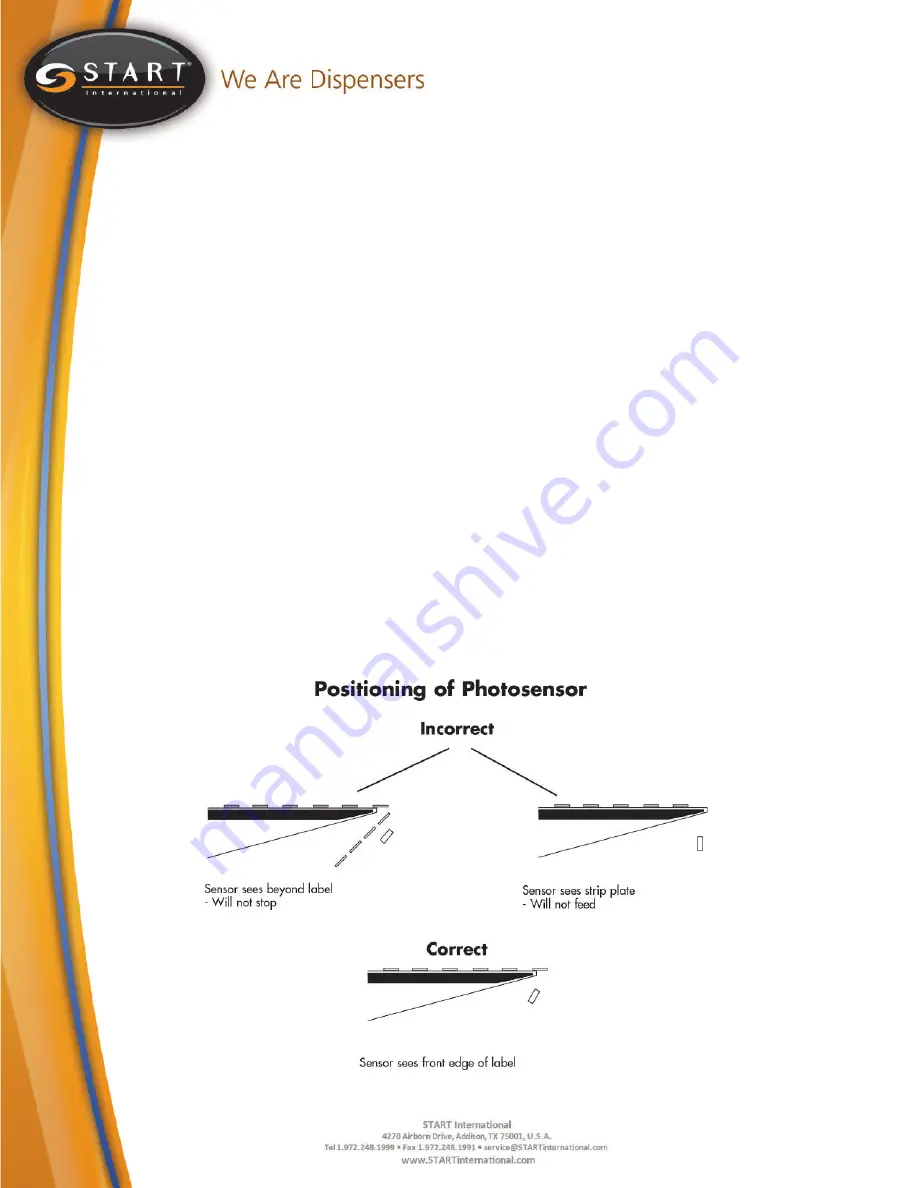

Photosensor:

The photosensor can be adjusted in any direction by using the lower thumbscrew on

the side of the machine and the thumbscrew underneath the photosensor bracket.

Loosening the thumbscrew on the side of the machine allows the photosensor to move

in and out. This is used to set the overhang distance of the label over the strip plate.

The thumbscrew underneath the photosensor bracket is used to swivel the sensor

along the front of the strip plate. When the label is being fed the correct distance, lock

the bracket in place. If there are 2 or more labels across, align the photosensor with the

last label to be removed. When these screws are locked in place, the machine is set.

Summary of Contents for LD3500 Series

Page 1: ...LD3500 Series ...

Page 3: ...EXPLODED VIEW ...

Page 6: ...QUICK START GUIDE ...

Page 7: ...QUICK START GUIDE ...