STAS -

Instructions for use moving floor

34

F. PREVENTIVE MAINTENANCE

Preventive maintenance on the trailer may be divided into the following sections:

•

Mechanical maintenance on the trailer (see § 1).

•

Maintenance on the bodywork of the trailer (see § 2).

•

Maintenance on the moving floor system (see § 3).

1. MECHANICAL MAINTENANCE

1.1. VISUAL INSPECTION

1.2. TYRES

A general visual inspection of the trailer should be carried out at regular intervals and any damaged or faulty compo-

nents must be replaced or repaired immediately.

Visually check the tyre pressures before each trip. Tyre pressures should be measured weekly and adjusted if required.

The table below shows the recommended tyre pressure and rims for the most common tyre sizes. If the trailer is fitted

with a different tyre size, the correct tyre pressure may be obtained from the manufacturer.

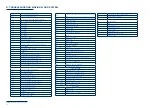

Tyre size

Rim width (advice)

Recommended tyre pressure (bar)

425/55 R19.5

13.00 x 19.5

9

445/45 R19.5

14.00 x 19.5

9

445/65 R19.5

14.00 x 19.5

8.5

11 x 22.5

7.50 x 22.5

8

12 x 22.5

8.25 x 22.5

8.5

13 x 22.5

9.00 x 22.5

8.5

365/80 R20

10.00 x 20

9

385/65 R22.5

11.75 x 22.5

9

425/65 R22.5

13.00 x 22.5

8.5

445/65 R22.5

14.00 x 22.5

9

Check whether the tyres of the trailer still contain the regulation grooves on a regular basis. Replace the tyres in time.

Inspecting the tyres is extremely important for your safety and the safety of others.

1.3. TIGHTENING TORQUES FOR BOLTS

All bolts and nuts should be inspected on a monthly basis. Particular attention should be paid to the bolts and nuts in the

floor system, the fifth wheel rubbing plate and the axle attachment to the chassis.

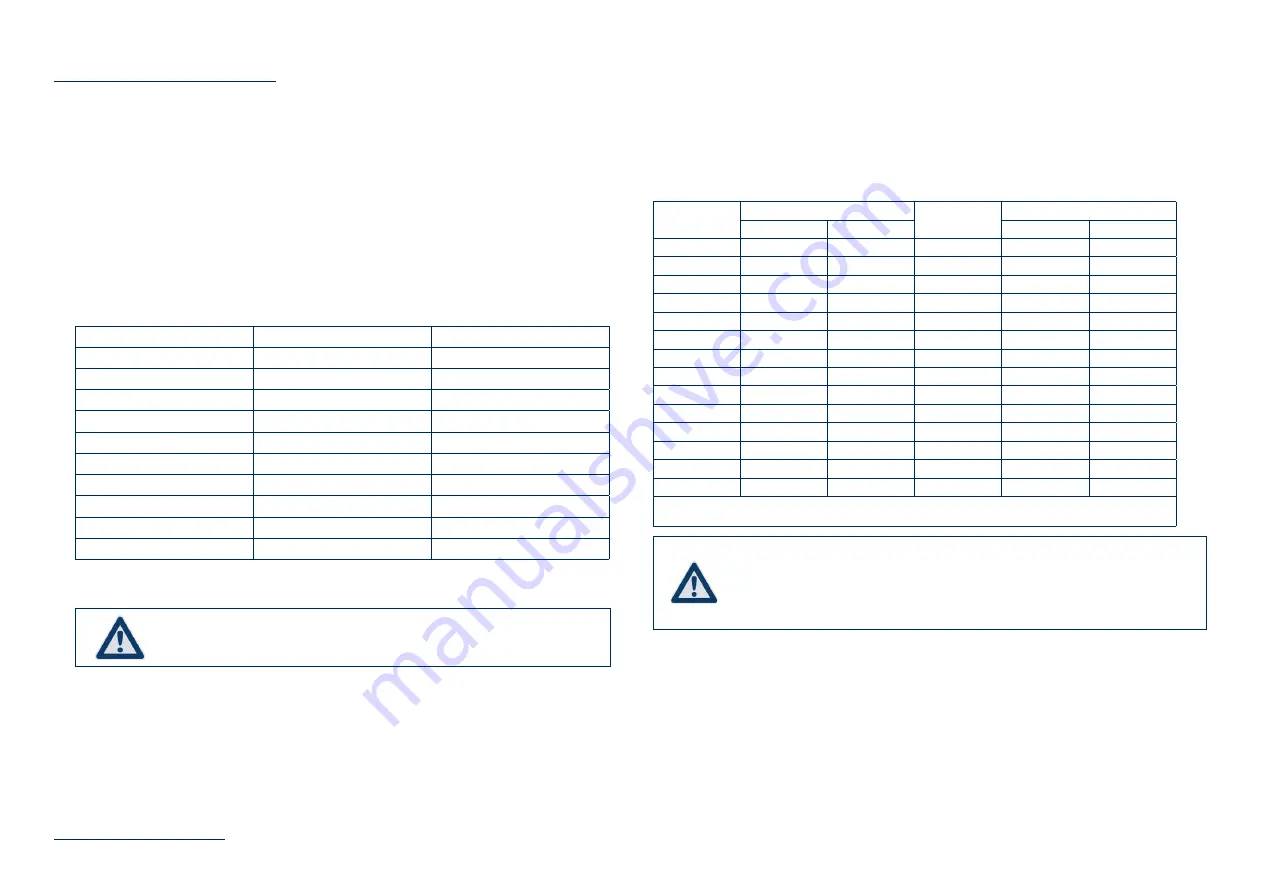

The following table indicates the tightening torques for normal construction bolts according to class 8.8 and class 10.9 (as

per DIN ISO 898 – Part 1).

Size

Tightening torque (Nm)

Size

Tightening torque (Nm)

Class 8.8

Class 10.9

Class 8.8

Class 10.9

M5

5.5

8.1

M20

425

610

M6

9.6

14

M20x1.5

475

680

M8

23

34

M22

580

820

M8x1

25

37

M22x1.5

630

900

M10

46

67

M24

730

1050

M10x1.25

49

71

M24x2

800

1150

M12

79

115

M27

1100

1550

M12x1.25

83

120

M27x2

1150

1650

M14

125

185

M30

1400

2000

M14x1.5

135

200

M30x2

1500

2150

M16

195

295

M36

2450

3500

M16x1.5

210

310

M36x2

2650

3780

M18

300

430

M42

3930

5600

M18x1.5

340

485

M42x2

4280

6050

The tightening torques listed are applicable up to M16x1.5 for bolts with galvanized surfaces and a surface rough-

ness of µ=0,125. On larger diameters, the surface roughness is µ=0,140.

The previously stated tightening torques do NOT apply:

•

to wheel nuts,

•

when lubricants such as MOS2 are used.

Please also refer to the additional documentation supplied with the trailer for

tightening torques relating to the floor system, axles, brakes and suspension.