Residen al Electric Water Heater Use and Care Guide • 23

faucet will help the tank drain faster.

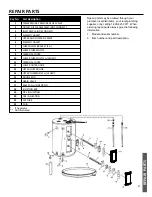

5

Remove the upper or lower

access panel on the water

heater, and then fold back the

insula on and remove the plas c

element/thermostat cover.

Figure 34 -

Access Panel

6

With the tank drained and

power o

ff

, remove the power

wires from the element you

intend to replace.

7

Remove the bad element using

an element wrench.

8

Make sure the new element is

the correct replacement by

referring to the water heater’s

data plate for voltage and wa age

informa on.

9

Clean the threads in the tank

opening with a rag. Insert the

new element equipped with a

rubber gasket. NOTE: Use a drop of

hand dishwashing liquid to lubricate the

gasket to help avoid damaging the

gasket as it is being ghtened. Tighten

with an element wrench.

NOTICE:

Do not turn power back on un l

the tank is completely full of water. For

complete instruc ons on

fi

lling the tank,

follow Step 8 in the Installa on sec on.

10

Re

fi

ll the tank by opening the

cold water supply valve. Make

sure a hot water faucet is open

and the drain valve is closed. Allow the

hot water to run full for at least three

minutes to make sure the tank has all

the air removed and is completely full

of water. Failure to perform this step

can cause the upper hea ng element to

burn out. Once you are certain the tank

is completely full of water, close the hot

water faucet.

Figure 35 -

Drain Valve

11

Check the newly installed

element for leaks. If a leak is

present, ghten the element

un l the leak stops. If you cannot stop

the leak, drain the tank and remove the

element. Inspect the gasket for dam-

age. If the gasket is damaged, replace

the gasket and re-install the element.

12

Once the element is success-

fully installed and there are no

leaks, replace the power wires,

thermostat cover, insula on, and access

panel. Make sure all wire connec ons

are ght. Replace the cover on the

electrical junc on box.

13

Restore power to the water

heater. It may take two hours

for the tank to heat up.

Replacing the Thermostat

WARNING! Working on an ener-

gized circuit can result in severe injury

or death from electrical shock. Turn

power o

ff

. Check wires with a non-con-

tact circuit tester to make sure power

is o

ff

. When you are

fi

nished, be sure

all covers are secured to reduce the

risk of

fi

re and electric shock.

To replace the thermostat, you’ll need

the following tools and supplies:

• A non-contact circuit tester. Always

turn power OFF

and check with a non-contact circuit tes-

ter before working on the water heater.

Figure 36 -

Upper and Lower Thermostats

• A replacement thermostat (available

at your local plumbing supplier).

Note that the upper and lower ther-

mostats are different (above). Some

models only have one thermostat.

• A business card to check the gap

between the thermostat and the tank

• Tape and a permanent marker to

mark the wires

• A flat blade and a Phillips screwdriver

Steps for Replacing the

Thermostat:

1

Turn the power OFF at the

circuit breaker or remove fuses.

NOTICE:

It is not necessary to drain the

tank to replace a thermostat.

2

Open the electrical junc on box

on top of the water heater. Using

a non-contact circuit tester, check

the power wires to make certain the

power is OFF.

Figure 37 -

Non-Contact Circuit Tester

MAINTENANCE