6

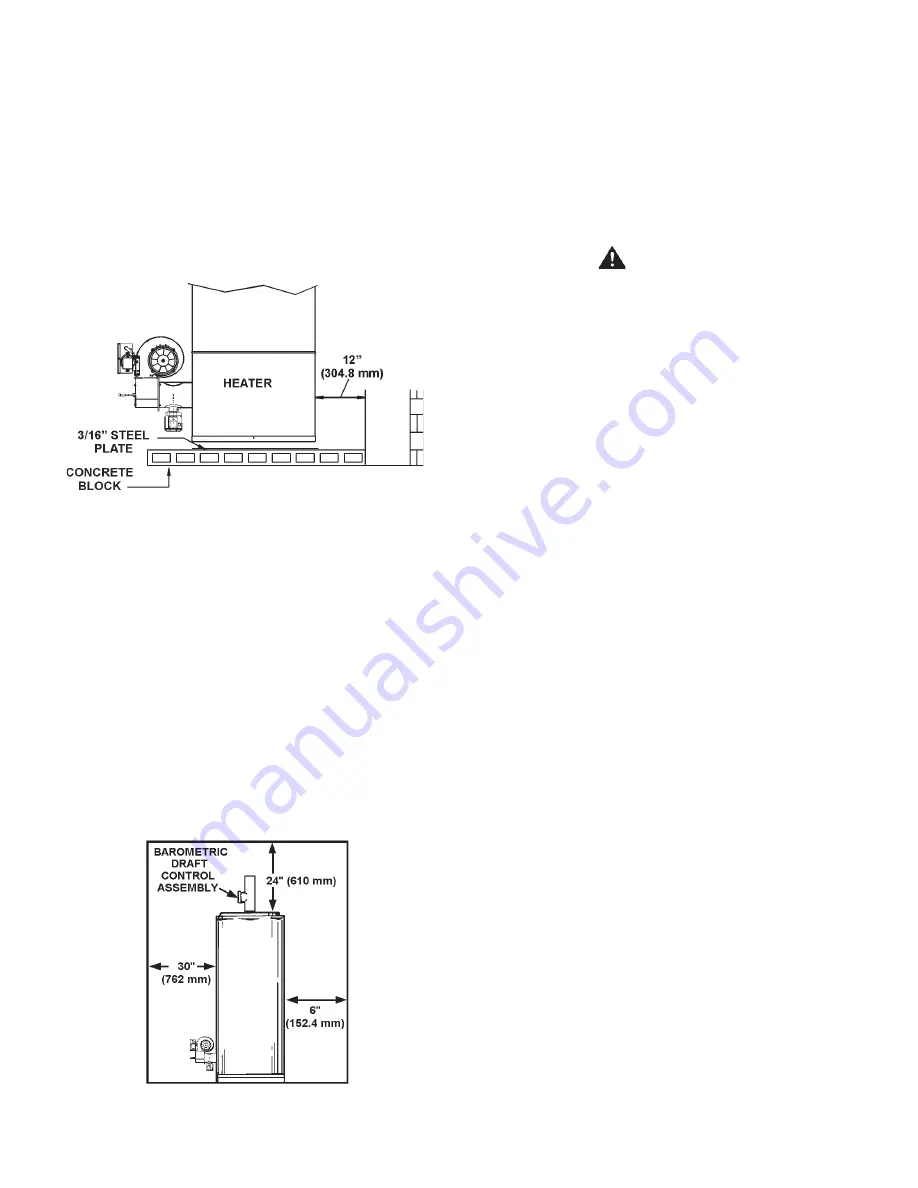

Units, which are to be installed on combustible flooring, must

be supported by a full layer of hollow concrete blocks, from

8” (203.2 mm) to 12” (304.8 mm) thick and extending

12” (304.8 mm) minimum beyond the heater in all directions.

The concrete blocks must provide an unbroken concrete surface

under the heater with the hollows running continuously and

horizontally. A 3/16-inch steel plate must cover the concrete

blocks, see Figure 2.

NOTE: If electrical conduits run under the floor of the proposed

heater location, insulate the floor as recommended above.

For appliances installation locations with elevations above 2000

feet (609.6 m), refer to HIGH ALTITUDE INSTALLATIONS section.

PROPER INSTALLATION ON COMBUSTIBLE FLOORING

FIGURE 2.

HARD WATER

Where hard water conditions exist, water softening or the

threshold type of water treatment is recommended. This will

protect the dishwasher, Coffee urns, water heaters, water piping

and other equipment.

See MAINTENANCE section for details of tank cleanout

procedure.

CLEARANCES

These heaters are designed for installation on non-combustible

flooring in an alcove with clearances to combustible construction

of 6” (152.4 mm) from the sides and rear, 24” (610 mm) from the

top with a 6” (152.4 mm) minimum between vent pipe and ceiling.

Minimum clearance from flue pipe to combustible material is

6” (152.4 mm), see Figure 3.

PROPER INSTALLATION CLEARANCES

FIGURE 3.

A clearance of 30” (762 mm) shall be maintained from

serviceable parts, such as power burners, relief valves flue

baffles, thermostats or drain valves.

AIR REQUIREMENTS

KEEP APPLIANCE AREA CLEAR AND FREE OF COMBUSTIBLE

MATERIALS, GASOLINE AND OTHER FLAMMABLE VAPORS AND

LIQUIDS.

DO NOT OBSTRUCT THE FLOW OF COMBUSTION OR

VENTILATING AIR.

WARNING

FOR SAFE OPERATION PROVIDE ADEQUATE AIR FOR

COMBUSTION AND VENTILATION. AN INSUFFICIENT SUPPLY

OF AIR WILL CAUSE RECIRCULATION OF COMBUSTION

PRODUCTS RESULTING IN AIR CONTAMINATION THAT MAY BE

HAZARDOUS TO LIFE. SUCH A CONDITION OFTEN WILL RESULT

IN A YELLOW, LUMINOUS BURNER FLAME, CAUSING

CARBONING OR SOOTING OF THE COMBUSTION CHAMBER,

BURNERS AND FLUE TUBES AND CREATES A RISK OF

ASPHYXIATION.

Where an exhaust fan is installed in the same room with a heater,

sufficient openings for air must be provided in the walls.

UNDERSIZED OPENINGS WILL CAUSE AIR TO BE DRAWN INTO

THE ROOM THROUGH THE CHIMNEY, CAUSING POOR

COMBUSTION. SOOTING MAY RESULT IN SERIOUS DAMAGE

TO THE HEATER AND RISK OF FIRE OR EXPLOSION.

UNCONFINED SPACE

In buildings of conventional frame, brick or stone construction,

unconfined spaces may provide adequate air for combustion

and ventilation.

If the unconfined space is within a building of tight construction,

(building using the following construction: weather stripping,

heavy insulation, caulking, vapor barrier, etc.), air for combustion

and ventilation must be obtained from outdoors or spaces freely

communicating with the outdoors. The installation instructions

for confined spaces in tightly constructed buildings must be

followed to ensure adequate air supply.

CONFINED SPACE

When drawing combustion and dilution air from inside a

conventionally constructed building to a confined space, such a

space shall be provided with two permanent openings, ONE IN

OR WITHIN 12 INCHES (304.8 mm) OF THE ENCLOSURE TOP

AND ONE IN OR WITHIN 12 INCHES (304.8 mm) OF THE

ENCLOSURE BOTTOM. Each opening shall have a free area of

at least one square inch per 1000 Btuh of the total input of all

appliances in the enclosure, but not less than 100 square inches.

If the confined space is within a building of tight construction, air

for combustion and ventilation must be obtained from outdoors.

When directly communication with the outdoors through vertical

ducts, two permanent openings, located in the above manner,

shall be provided. Each opening shall have a free area of not

less than one square inch per 4000 Btuh of the total input of all

appliances in the enclosure.

VENTING

THE INSTRUCTIONS IN THIS SECTION ON VENTING MUST BE

FOLLOWED TO AVOID CHOKED COMBUSTION OR

RECIRCULATION OF FLUE GASES. SUCH CONDITIONS CAUSE

SOOTING OR RISKS OF FIRE AND ASPHYXIATION.

Summary of Contents for GPG-540A

Page 20: ...20 FIGURE 11 ...

Page 21: ...21 FIGURE 12 ...

Page 25: ...25 PREMIX LOW NOx BURNER EXPLODED VIEW FOR GPG MODELS FIGURE 13 ...

Page 26: ...26 PREMIX LOW NOx BURNER EXPLODED VIEW FOR GPV MODELS FIGURE 14 ...

Page 36: ...36 GPG BURNER ASSEMBLY Part numbers are listed on page 37 ...

Page 38: ...38 GPV BURNER ASSEMBLY Part numbers are listed on page 39 ...