ENGLISH

13

13

This manual is consistent with the manufacture date of the

purchased tool, information you will find on the technical

data label on the tool. Find user guide updates in our

website:

www.grupostayer.com

Safety instructions

Always properly fix the workpiece with a

clamp.

Never hold the workpiece with your

hands or make cuts without the workpiece

fixed.

When tightening the clamp (clockwise)

make sure it is on the right position.

Otherwise the

workpiece may not be properly fixed.

Never adjust, release or tighten the clamp while the

tool is functioning.

Keep your hands and body away from the cutting

zone and from the disc. Don’t try to reach for objects

around, under or through the saw.

Check the blade protector after every use. Don’t

use the tool if the protector doesn’t moove freely or

doesn’t close instantly.

Never fix the blade protector in an open position.

Check that the carter is working as intended. If it’s not

it must be checked before using the tool.

The carter

may malfunction if it has damaged components or due to

debris accumulation.

Do not use abrasive discs with this tool. This tool

is specifically designed to be exclusively used with

metal cutting widia discs.

Always use shrapened discs with the right size. No

fitting blades will spin excentrically, loosing disc

control.

Never use clamps or tools that have not been supplied

by the manufacturer or that are damaged.The included

accessories have been specially designed for the best

performance and safety with this chop saw.

Always check the blade maximum speed and make

sure it exceeds the maximum tool speed.

Don’t use damaged or blunt discs.

There may be recoil.

Be careful to not bend or force the disc.

The blade may

be damaged.

Keep the tool on an isolated surface where it can be

held or fixed avoiding contact with cables or hidden

objects.

Cable contact may cause an electrical surge

through the tool damaging the user.

Recoil

If the disc is bent or misaligned during the cutting process,

the teeth may excesively bite the cutting material causing

the disc to jump or to eject the cutting material at high

speeds, injuring the user. Recoil is the outcome of tool

missusage or a wrong working procedure. This can be

avoided following this guidelines:

Keep the chop saw firmly held and position your arm

and body in order to be able to resist recoil forces.

Recoil forces can be contained by the user if this guidelines

are followed.

When the disc gets stuck or the cut is interrupted ,

release the trigger and hold the chop saw still until

the disc stops completely

. Never try to remoive the disc

while it’s still spinning as there may be recoil. Check the

tool and the circumstances that may have caused the

situation.

When restarting a cutting task that was interrupted,

center the disc in the same cut and check that it

doesn’t get stuck on the cutting material.

If the disc

stops, it may pass over the surface or cause recoil while

the saw gets restarted.

Propperly fix and hold big workpieces to reduce recoil

risks.

Big workpieces tend to fall under their own weight.

Supports must be placed under the workpiece on both

sides close to the cutting line and the worpiece edges.

Never use damaged discs.

Damaged discs may cause

excesive friction, causing recoil.

The disc spindle must be propperly tightened and

fixed when making cuts.

If the nut loosens during the

cut, it may cause recoil and the workpiece ejection at

great speed.

Only use suitable metal cutting widia discs.

Propperly tighten all the fixing nuts and bolts to

secure the disc before cutting.

Propperly fix the workpiece.

The piece must be firmly

and tightly fixed to avoid movements.

Allow the disc to completely stop before changing it

or changing the cutting angle.

Check the disc surface

as well as both sides and teeth

to remove ani debris there may be stuck.

Check that de disc

is not defective or broken before

starting each cut. Replace broken discs with new ones

immediately.

Never switch on the tool

with the workpiece in contact

with the disc.

Allow the motor to reach its maximum speed before

starting to cut.

Summary of Contents for TD355B

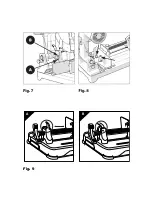

Page 2: ...4 5 1 6 2 3 7...

Page 3: ...A B Fig 9...