ENGLISH

15

15

WARNING: After installing a new disc switch on the tool

and let it run without load for several minutes.

Stay away from the disc. If the disc has an undetected issue

it can be noticed with this procedure.

Using the cutting guide and clamp

Warning:

Always use the clamp with no exceptions. If the

workpiece can’t be secured with the clamp do not use it.

Cutting withous safety may cause recoil and accidents.

Always secure the piece in the most stable ans safe

manner. Make sure the workpiece is firmly fixed to the

saw. the 45º cutting guide spins freely to reach the cutting

angle.

Adjust the cutting angle

Note

: the rear clamp can be spinned up to 45º

The rear clamp can be adjusted to 0º (90º towards the

disc) So the disc can cut the material directly placed on

the clamp.

For angle cuts, the rear clamp can be adjusted up to 45º,

With an angle meter for maximum precission.

To adjust the rear clamp angle:

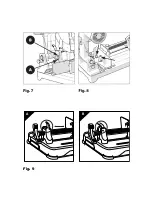

• Loosen the screw M10 and the lever screw. (Fig. 8)

• Spin the clamp to the desired angle.

• Tighten both screws again with the provided hex key.

Note: The lever screw has a coil that alows to reposition

the clamp. Repositioning the lever might be needed to

completely tighten when the rear angle clamp is being

adjusted. To reposition the handle on the screw, pull the

lever upwards and spin it to the desired position (allowing

to tighten the screw) release the lever and tighten the

screw. The fron clamp will automatically compensate any

angle from the rear clamp or the irregulartities from the

workpiece.

Using the clamp

The screw has a simple release system.

- Place the workpiece against the guide in the most safe

manner as possible.

- Lift the split nut. (Fig. 9a)

- Slide the fron clamp to the desired position.

- Place back the split nut. (Fig 9 b)

Warning:

You must place back the split nut in its original

position and properly adjust it to the clamp. Pulling a little

bit the clamp handle just before the sclamp touches the

workpiece will improve the split nut fixing. Using the tool

without the split nut installed is dangerous and should be

avoided.

- Tighten the clamp to secure the workpiece.

- Check the workpiece is properly fixed before working.

Cutting head course

The cutting depth is set from factory and may not need

further adjustments. If the tool is disassembled or for any

other reason the cutting depth needs to be adjusted to

avoid the disc touching the base.

Lower the head and check if the disc has any contact with

the base.

- Release the nut on the cutting limit. (Fig. 7a)

- Spin the screw outwards (Fig. 7b) (counterclockwise) to

reduce the cutting depth.

- Spin the screw inwards (clockwise) to increase the

cutting depth.

- Tighten the nut back when you achieve the desired

cutting depth.

Switch ON /OFF

Make sure the power source matches the tool requirements

and that the trigger is “SWITCHED OFF” before plugging

it to the power source.

This tool includes a safety trigger to switch it on:

- Press the safety lock button with a finger while holding

the handle.

- Press the main trigger at the same time to switch on the

tool.

WARNING: Never switch on the tool while the disc is

in contact with any surface or material

Debris removal

This tool has a metal debris deposit.

Once the deposit is full the debris must be removed. To do

this unplug the tool from the power source..

To check the debris deposit:

- Spin the lock lever horizontally to access the deposit.

- Empty the deposit in a suitable recycling point.

- It is advisable to use a breathing mask to empty the

deposit.

- Place back the deposit and spin the lever vertically to fix

it to the tool.

Freshly cut debris might be sharp and very hot. Be careful

when removing them, avoid touching them with your

hands or body. Do not dispose of debris on any bin or

container as they may cause a fire.

Safety transport chain use

To increase the safety whil transporting the tool the safety

chain must be used.Simply lower the head and place the

chain so the head stays down.

Lower saw guards

This guardar are really important for your safety.

Each time you use the saw make sure they can rotate

freely and that they quickly return to their original position.

Before using the tool clean any dust and debry that migh

be around the carter. DO NOT LUBRICATE THIS ZONE,

FIRE WARNING.

The carter has a lubrified dry coating

. NEVER block

the carter on an open position. NEVER use the saw if you

are not working.

If the saw is slow take it to the closest customer service

available.

Summary of Contents for TD355B

Page 2: ...4 5 1 6 2 3 7...

Page 3: ...A B Fig 9...