ENGLISH

16

16

Tool usage

NOTE

: Remember that despite being really similar to

an abrasive chop saw, this tool requires less force and

pressure to be operated.

Make sure the workpiece is fixed and tightened according

to the users guide. The workpiece must be completely

fixed and straight before making any cut. Make sure the

workpiece has the proper support to avoid accidents.

Check the lower guards to make sure they work as

intended. Press the trigger and allow the motor to reach

its maximum speed. Press the carter lever with your thum

and slowly lower the tool head until the disc touches the

workpiece and starts cutting. remember to stay sideways

towards the saw. Always be careful. As you cut do not make

excessive force, there is no need to force the cut. Allow

the saw to complete the cut at its own speed according

to the material to be cut. Increase pressure over thicker

materials. Do not apply pressure over thin materials.

Warning: If the saw blade gets stuck while cutting

release immediately the trigger to swithc the tool off.

After completing the cut, rise the cutting head until the disc

is no longer in contact with anything before releasing the

trigger. Make sure the tool has completely stopped before

removing the workpiece or making any further actions.

Maintenance

use compressed air to blow the tool holes periodically.

Clean every plastic component with a damp cloth. NEVER

use chemicals to clean the plastic pieces, they may get

damaged. Use protection glasses while using compressed

air. We recommend taking the tool to a technical support

once a year for a full clean & check.

Maintenance and service

Before any work on the machine itself, pull the

mains plug.

Clean the ventilation slots of your power tool

regularly with a soft brush.

If the machine should fail despite the care taken in

manufacturing and testing procedures, repair should be

carried out by an after-sales service centre for

STAYER

power tools.

Repair service

Our after-sales service responds to your questions

concerning maintenance and repair of your product as

well as spare parts. Exploded views and information on

spare parts can also be found under:

info@grupostayer.com

Our customer consultants answer your questions

concerning best buy, application and adjustment of

products and accessories.

Warranty

Warranty card

Included in the documentation that accompanies this

equipment, you should find the warranty card. You should

fill out the card completely and return to vendor with a

copy of purchasing receipt or invoice and you should

receive a receipt.

Note:

If you cannot find the warranty card within the

documentation, you must ask for it through your supplier.

The warranty is limited only to manufacturing defects and

expire if pieces have been removed or manipulated or

repaired other than the manufacturer.

Disposal and recycling

The machine, accessories and packaging should be sor-

ted for environmental-friendly recycling.

Only for EC countries:

Do not dispose of power tools into household waste!

According the European Guideline 2012/19/EC for

Waste Electrical and Electronic Equipment and its

implementation into national right, power tools that

are no longer usable must be collected separately

and disposed of in an environmentally correct

manner.

Subject to change without notice.

6. Regulations

6.1 Technical features

Ø

Ø

x

y

= Power

= No load speed

= Disc size

= Cutting width

= Cutting depth

= Mass

L

WA

= Sound power level

L

PA

= Sound pressure level

= Vibration

The values given are valid for nominal voltages [U]

230/240 V ~ 50/60 Hz - 110/120 V ~ 60Hz. For lower

voltage and models for specific countries, these values

can vary. Please observe the article number on the type

plate of your machine. The trade names of the individual

machines may vary.

Summary of Contents for TD355B

Page 2: ...4 5 1 6 2 3 7...

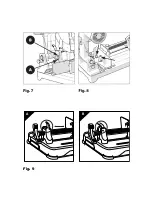

Page 3: ...A B Fig 9...