12

Troubleshooting

The power cord is not plugged in.

The motor’s thermal overload protection

has tripped.

POSSIBLE CAUSE

PROBLEM

The motor will

not run or start

Plug the power cord into a grounded outlet.

Set the on/off switch to the ON position.

The on/off switch is in the O (OFF)position.

The extension cord is the wrong wire

gauge or is too long.

A fuse has blown or a circuit breaker has

been tripped.

The air tank pressure exceeds the preset

pressure switch limit.

The safety valve is stuck open.

Electrical connections are lose.

The motor, capacitor or safety valve is

defective.

The motor runs

continuously when

the ON/OFF switch

is in the ON

position.

Check extension cord information (page 7) for the

proper wire gauge and cord length.

Turn the air compressor off, unplug the power cord and

wait until the motor has cooled down. Plug in the power

cord only after the motor has cooled down, and wait

at least 5 minutes to make sure the thermal overload

protector has recovered.

Replace the fuse or reset the circuit breaker.

Verify that the fuse has the proper amperage.

Check for low voltage conditions.

Disconnect any other electrical appliances from the

circuit or operate the compressor on a dedicated circuit.

The motor will start automatically when the tank

pressure drops below the cut-in pressure.

Clean or replace the safety valve.

Contact an authorized service center, or call

1-888-899-0146

Contact an authorized service center, or call

1-888-899-0146

Set the ON/OFF switch to the OFF position. If the motor

does not shut off, unplug the air compressor. If the

pressure switch is defective, replace it.

Check the air requirements of the accessory that is

being used. If it is higher than the CFM (Cubic Feet per

Minute) and pressure supplied by the compressor

(page 18), a larger capacity air compressor is needed.

Most accessories are rated at 25% of actual CFM while

running continuously.

The ON/OFF switch does not shut off the

motor when the air compressor reaches

the cut-out pressure and the safety valve

activates.

The compressor’s capacity is not enough.

The regulator does

not regulate the

pressure.

The regulator or its internal parts are dirty

or damaged.

Replace the regulator.

SOLUTIONS

Summary of Contents for 3332081

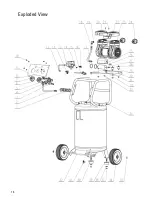

Page 14: ...14 Exploded View...