5

DO NOT OPERATE THIS UNIT UNTIL YOU READ AND UNDERSTAND THIS

INSTRUCTION MANUAL FOR SAFETY, OPERATION, AND MAINTENANCE

INSTRUCTIONS.

compressor.

.

High pressure air could result in death or serious injury.

Never operate above maximum operating pressure of the spray gun or tool. Drain water from tank after each

use. Do not weld or repair tank.

Do not operate with pressure switch or safety valve set above maximum allowable working pressure.

Hot compressors surfaces could result in serious injury. Allow compressor to cool before touching.

Inhalation hazard. Using compressor to supply breathing air could result in death or serious injury. Do not

use compressor to supply breathing air.

Risk of serious eye injury. Always wear ANSI Z87.1 approved safety goggles when using air compressor. Do

not spray any part of the body.

Safety Information

Shock risk could result in death or serious injury. Only connect compressor to a properly grounded

receptacle. KEEP CHILDREN AWAY FROM THE AIR COMPRESSOR AT ALL TIMES.

WARNING

Do not restrict compressor ventilation openings or place objects against or on top of compressor. Operate

compressor only in a clean, dry, well ventilated area.

Do not operate unattended. Always turn off and unplug unit when not in use.

Do not spray flammable materials in vicinity of any flame or ignition sources including the compressor unit.

Risk of fire could result in death or serious injury.

Dust can be created when cutting, sanding, drilling or grinding materials such as wood, paint, metal,

concrete, cement, or other masonry. To reduce your exposure to these chemicals, work in a well ventilated

area and ALWAYS wear approved safety equipment.

This product can expose you to chemicals including lead, which is known to the State of Calif

ornia to

cause cancer, birth defects or other reproductive harm. For more information go to www.P65Warnings.ca.gov.

WARNING:

Summary of Contents for 3332081

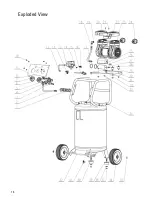

Page 14: ...14 Exploded View...