INSTALLATION, OPERATION & MAINTENANCE MANUAL

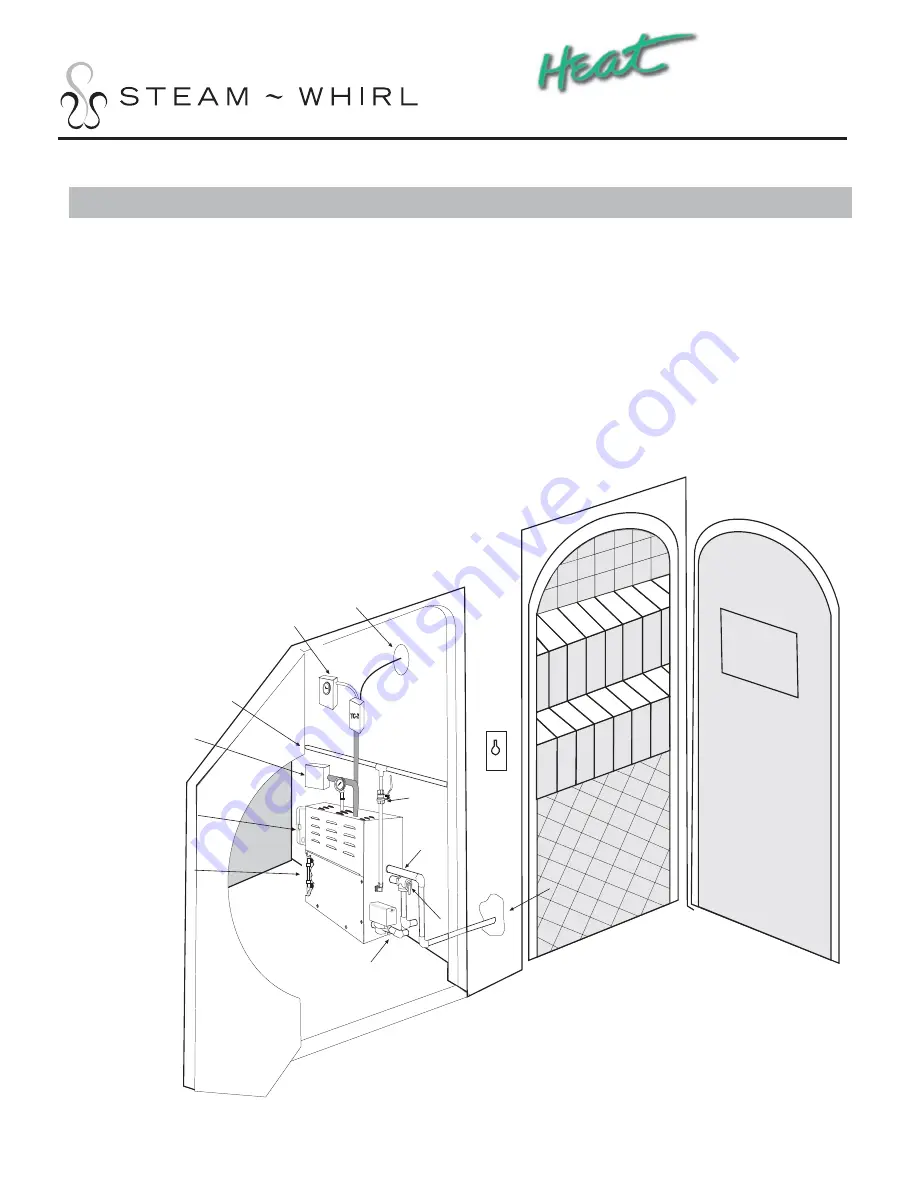

1. Place the steam generator, optional Thermostat Controller (TC-2) and optional 24 Hr 7 Day Timer in a location

NOT ACCESSIBLE TO CLIENTS

but that is

ACCESSIBLE TO MAINTENANCE

and not more than 40’ from

steam room.

ALL

steam generators require maintenance.

2. The steam generator should never be located where it is exposed to outside weather conditions or freezing

temperatures, near fl ammable materials, inside the steam room or where access cannot be gained to Water Level

Sensor Probe for maintenance.

3. Install in an upright and level position.

4. The serial number label should be visible and accessible for service.

5. A minimum of 2’ of open unobstructed space must be left around the top and sides of the generator to allow for

heat dissipation and accessibility for service.

INSTALLATION

Steam

Room

24 H Timer

for

Blowdown

24 Hr/7 Day Timer

for TC-2

Water

Supply

Line

A

C

D

E

F

B

Site Glass

Temperature

Sensor Probe

Optional

60 Min

Timer

STEAM-WHIRL

A

Power Box

&

Power Disconnect

TC-2

G

Spa Kur Therapy

Development

Inc

H-e-a-t Spa Kur Therapy Development Inc — Tel 707-942-6633 — Fax 707-942-0734 — www.h-e-a-t.com

6/20