05/11

Pub. No. 200-G

- 2 -

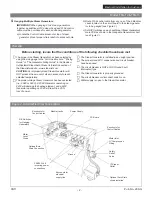

Optional Auto Drain

shown installed

Power Supply

Modular Jacks

Knockouts for

Control Cables

PC Board

Knockouts for

Control Cables

Knockouts for

electrical

supply line

208/240 Volt

incoming power

connections

Ground

Optional Auto

Drain Connection

Water Inlet

⅜

" Compression

Fitting

¾" Steam

Outlet

Safety

Relief

Valve

Water

Level

Probe

DIP Switches

for Ganging

Generators

Electrical Installation Instructions

Figure 2 - Internal Electrical Connections

The Steam Generator is installed in an upright position.

The proper sized 90°C copper wire and circuit breaker

have been used.

The circuit breaker is NOT a GFI (Ground Fault

Interrupter) type.

The Steam Generator is properly grounded.

The circuit breaker or disconnect switch is on.

Water supply is open to the Steam Generator.

Checklist

Before starting, insure that the conditions of the following checklist have been met:

The proper size Steam Generator has been selected by

using the sizing page in the “Full Line Brochure,” “Pricing

Guide,” or “The Generator Sizing Guide” in the Residen-

tial Systems/Steambath Product Information section of

the Steamist website - www.steamist.com.

CAUTION:

An improperly sized Steam Generator will

NOT produce the amount of steam necessary to reach

selected temperature.

The proper voltage Steam Generator has been selected

(i.e., 208V or 240V). A 208V Generator operating on

240V will damage the heating element, and a 240V

Generator operating on 208V will result in a 25%

loss of power.

5.

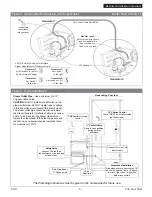

Ganging Mulltiple Steam Generators

IMPORTANT:

When ganging 2 to 4 steam generators

together an additional 3199 steam head and 5158 control

cable must be purchased for each additional generator.

a) Locate the Control Cable knockout at top of steam

generator. Mount proper strain relief into knockout hole.

b) Route 5158 control cable from any one of the 4 Modular

Jacks located on the circuit board to the steam genera-

tor to be ganged (see Figure 3).

c) Set DIP Switches on each additional Steam Generator's

main PCB as shown in the Gangable Generators chart

(see Figure 3).

Model: TSG-12 & TSG-15