O V E R V I E W

9

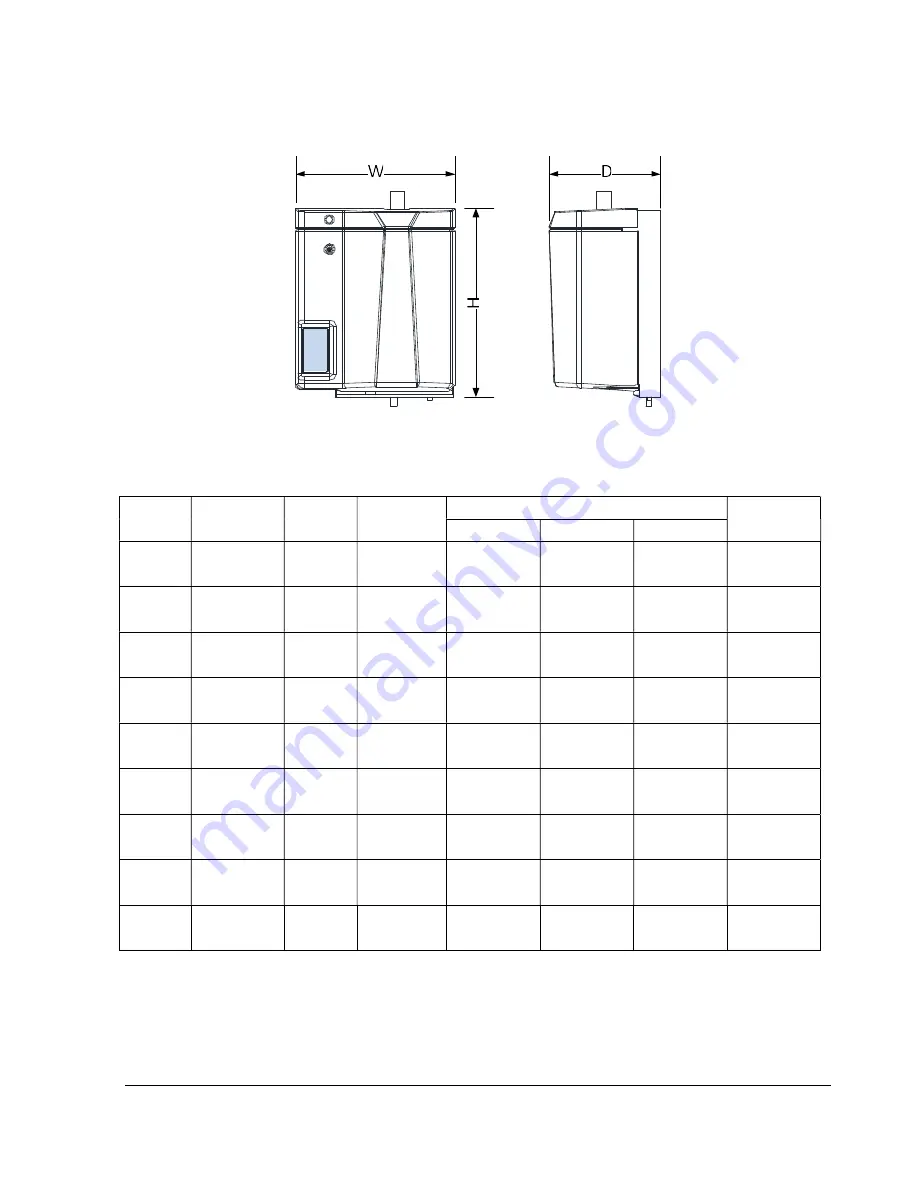

IER Dimensions

Figure 3 – IER Dimensions

Model

Steam

Capacity

Nb Cyl

+ size

Nb Steam

Ø

Dimensions

Net

weight

W

H

D

IER-04

10lb/h

[4.5kg/h]

1x

small

1x 1.5po

[DN40]

20in

[510mm]

23in

[585mm]

13in

[330mm]

55lb

[25kg]

IER-05

15lb/h

[6.8kg/h]

1x

small

1x 1.5po

[DN40]

20in

[510mm]

23in

[585mm]

13in

[330mm]

55lb

[25kg]

IER-09

24lb/h

[11.4kg/h]

1x

small

1x 1.5po

[DN40]

20in

[510mm]

23in

[585mm]

13in

[330mm]

55lb

[25kg]

IER-12

35lb/h

[15.9kg/h]

1x

medium

1x 2po

[DN50]

23in

[585mm]

27in

[686mm]

17in

[432mm]

73lb

[34kg]

IER-17

50lb/h

[22.7kg/h]

1x

medium

1x 2po

[DN50]

23in

[585mm]

27in

[686mm]

17in

[432mm]

73lb

[34kg]

IER-22

65lb/h

[29.5kg/h]

1x

medium

1x 2po

[DN50]

23in

[585mm]

27in

[686mm]

17in

[432mm]

73lb

[34kg]

IER-31

93lb/h

[42.3kg/h]

1x

medium

1x 2po

[DN50]

23in

[585mm]

27in

[686mm]

17in

[432mm]

73lb

[34kg]

IER-44

130lb/h

[59.1kg/h]

2x

medium

2x 2po

[DN50]

42in

[1067mm]

27in

[686mm]

17in

[432mm]

146lb

[67kg]

IER-62

185lb/h

[84.1kg/h]

2x

medium

2x 2po

[DN50]

42in

[1067mm]

27in

[686mm]

17in

[432mm]

146lb

[67kg]

Summary of Contents for IER-04 Series

Page 2: ......