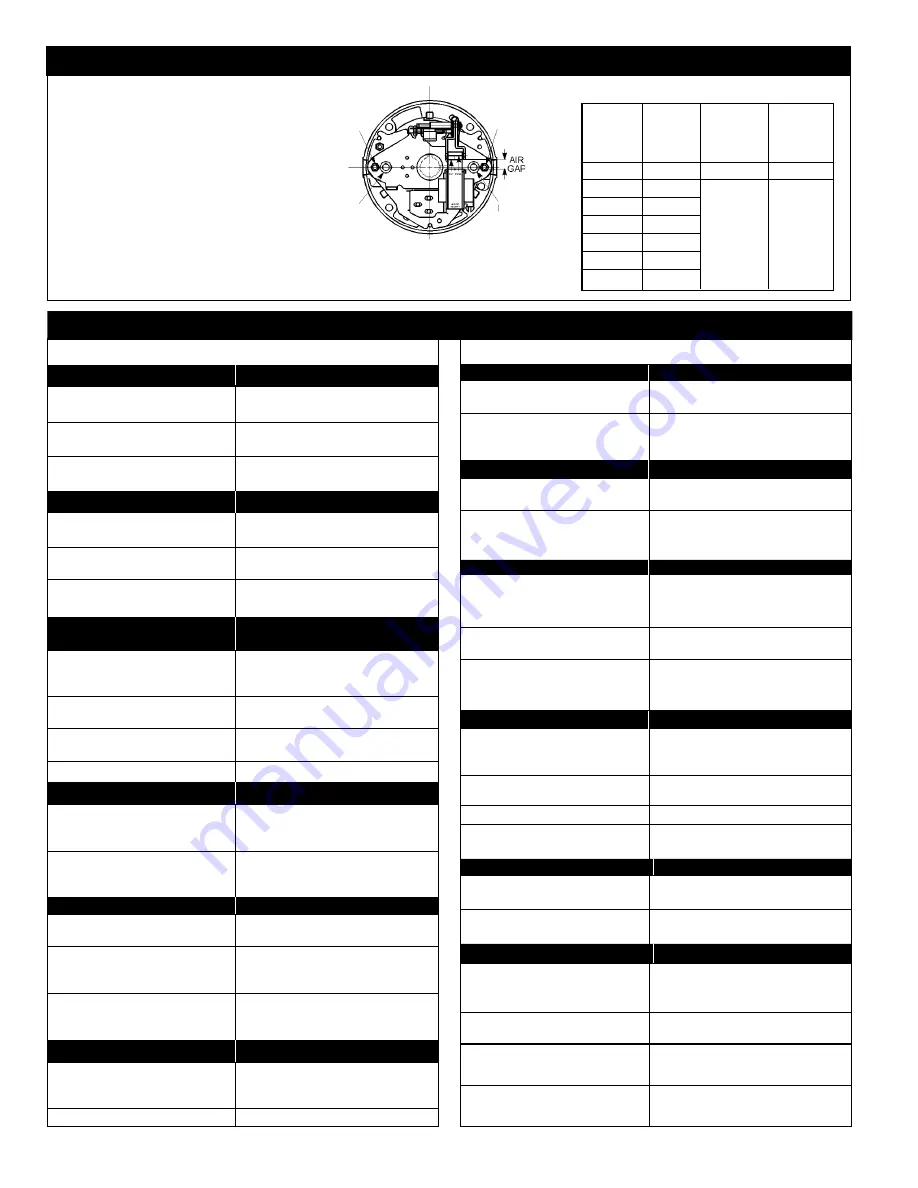

Torque Adjustment

Brake is factory set for nominal rated static

torque which is maximum torque. Torque

may be decreased up to 50% for increased

stopping times up to 2 second stop time.

The torque on the 1-1/2 lb-ft brake may not

be reduced.

Turn both spring adjustment screws (11),

Figure 3, equal amounts counterclockwise

to decrease torque. See Table A for torque

reduction permissible amounts.

11

11

10

10

Figure 3

Nominal Original Maximum % Torque

Static Spring Counter- Reduction

Torque Height clockwise

per

(lb-ft) (inches) Turns

Turn

1-1/2

1.56”

-

-

3

1.50”

6

1.47”

10

1.53”

7

7%

15

1.53”

20

1.53”

25

1.47”

TABLE A

COIL FAILURE

SUPPLY VOLTAGE CAUSE

SUPPLY VOLTAGE CORRECTION

Line voltage >110% of coil rating Reduce voltage or replace with prop-

er rated coil

AC input on a DC coil

Replace rectifier or replace with

proper rated coil.

Excessive voltage drop during

inrush time

Increase current rating of power

supply.

WIRING CAUSE

WIRING CORRECTION

Leadwires interfering with plunger

pull-in

Reroute wiring away from plunger

and other moving components.

Excessive voltage drop during

inrush time

Increase leadwires size from power

supply

Coil leadwire shorted to ground

Replace coil or leadwire and protect

with wire sleeving

SOLENOID ASSEMBLY CAUSE

SOLENOID ASSEMBLY

CORRECTION

Plunger not seating flush against

solenoid frame

Loosen solenoid mounting screws

and reposition frame to allow full

face contact

Plunger cocked in coil preventing

pull-in

Realign solenoid frame

Excessive solenoid/plunger wear

at mating surface

Replace solenoid assembly

Broken shading coils

Replace solenoid assembly

WORN PARTS CAUSE

WORN PARTS CORRECTION

Excessive wear of solenoid link

arm and/or shoulder bolt

Replace link arm and link bolt; also

inspect plunger thru-hole for

elongation

Plunger guides worn down and

interfering with plunger

movement

Replace guides

APPLICATION CAUSE

APPLICATION CORRECTION

Machinery cycle rate is exceeding

brake rating

Reduce brake cycle rate or use alter-

nate control method

High ambient temperature

(>110%) and thermal load

exceeding coil insulation rating

Use Class H rated coil and /or find

alternate method of cooling brake

Brake coil wired with windings of

an Inverter motor or other

voltage/current limiting device

Wire coil to dedicated power source

with instantaneous coil rated voltage

MISCELLANEOUS CAUSE

MISCELLANEOUS CORRECTION

Wrong or over tightened torque

Replace with proper spring or refer

to Installation section for proper

spring height

Excessive air gap

Reset, refer to Installation Section 4

EXCESSIVE WEAR / OVERHEATING

AIR GAP CAUSE

AIR GAP CORRECTION

Low solenoid air gap

Reset air gap (refer to Air Gap

Adjustment)

Disc pack dragging

Inspect endplate, hub and discs for

dirt, burrs, wiring and other sources

of interference preventing disc “float”

CYCLE RATE CAUSE

CYCLE RATE CORRECTION

Brake “jogging” exceeding coil

cycle rate

Reduce cycle rate or consider alter-

nate control method

Thermal capacity is being

exceeded

Reduce cycle rate, use alternate

control method or increase brake

size

ALIGNMENT CAUSE

ALIGNMENT CORRECTION

Broke endplate not concentric to

motor C-Face

Motor register must be within

.004” on concentricity;

Motor shaft runout is excessive

Must be within .002”; runout;

consult motor manufacturer

Brake is being operated on a

incline greater than 15° above or

below horizontal

Vertical separator springs must be

used to prevent discs from

becoming cocked

WORN PARTS CAUSE

WORN PARTS CORRECTION

Friction disc excessively worn

(disc can wear to 1/2 original

thickness or .093”)

Replace friction discs.

Endplate, stationary disc or

pressure plate warped

Replace warped or worn component

Linkages and/or pivot pins worn

Replace all worn components

Motor shaft endfloat excessive

Endfloat must not exceed .020”; con-

sult motor manufacturer

HUB CAUSE

HUB CORRECTION

Burr on hub interfering with disc

“float”

File off burr

Set screw backed out and

interfering with disc

Retighten set screw; use Loctite®

242 to help secure

MISCELLANEOUS

MISCELLANEOUS

Solenoid plunger not pulling

completely

Check line voltage (±10% of

nameplate rating) or replace worn

solenoid assembly

Wiring is restricting disc pack

movement

Reroute wiring

Excessive stop time

(2 seconds or greater)

Increase brake size/torque or use

alternate control method

High Ambient temperature

(in excess of 110°F)

Reduce cycle rate or use alternate

method of cooling

TROUBLESHOOTING

Rexnord Industries, LLC, Stearns Division, 5150 S. International Dr., Cudahy, WI 53110, (414) 272-1100 Fax: (414) 277-4364 www.stearnsbrakes.com

TORQUE ADJUSTMENT