Installation and Service Instructions for

87,000; 87,100; 87,200; 87,400 and 87,600 Series

Important

Please read these instructions carefully before

installing, operating, or servicing your Stearns

brake. Failure to comply with these instructions

could cause injury to personnel and/or damage

to property if the brake is installed or operated

incorrectly. For definition of limited warranty/

liability, contact Rexnord Industries, LLC,

Stearns Division, 5150 International Dr.,

Cudahy, WI 53110, (414) 272-1100.

Caution

1. Installation and servicing must be made

in compliance with all local safety codes

including Occupational Safety and Health

Act (OSHA). All wiring and electrical

connections must comply with the National

Electric Code (NEC) and local electric

codes in effect.

2. Use of this brake in atmospheres

containing explosive gases and dusts

must be in accordance with NEC article

501. This brake is not suitable for use in

certain atmospheres containing explosive

gases and dusts.

HazLoc

inspection

authorities are responsible for verifying and

authorizing the use of suitably designed

and installed

HazLoc

equipment. When

questions arise consult local

Authority

Having Jurisdiction (AHJ)

.

3. To prevent an electrical hazard, disconnect

power source before working on the brake.

If power disconnect point is out of sight,

lock disconnect in the

off

position and tag

to prevent accidental application of power.

4. Make certain power source conforms to

the requirements specified on the brake

nameplate.

5. Be careful when touching the exterior of an

operating brake. Allow sufficient time for

brake to cool before disassembly. Surfaces

may be hot enough to be painful or cause

injury.

6. Do not operate brake with housing

removed. All moving parts should be

guarded.

7. Installation and servicing should be

performed only by qualified personnel

familiar with the construction and operation

of the brake.

8. For proper performance and operation,

only genuine Stearns parts should be used

for repairs and replacements.

9. After usage, the brake interior will contain

burnt and degraded friction material

dust. This dust must be removed before

servicing or adjusting the brake.

DO NOT BLOW OFF DUST using an air

hose. It is important to avoid dispersing

dust into the air or inhaling it, as this may

be dangerous to your health.

a. Wear a filtered mask or a respirator

while removing dust from the inside of

a brake.

b. Use a vacuum cleaner or a soft brush

to remove dust from the brake. When

brushing, avoid causing the dust to

become airborne. Collect the dust in a

container, such as a bag, which can be

sealed off.

10. Do not run motor with the brake in

the manual release position to avoid

overheating of friction disc.

11. Do not lubricate any parts of the brake.

12. Do not adjust brake torque. The nominal

static torque is factory pre-set and should

not be altered.

General Description

The 87,X00 Series is a spring-set, electrically

released disc brake for controlled stopping and

holding of a load. It is self-adjusting for friction

disc wear and mounts directly to a NEMA

C-face motor with 8-1/2” (AK) register and a

7-1/4” (AJ) bolt circle.

The 87,100 Series Brake mounts to a

10-1/2” AK diameter register and 9” (AJ) bolt

circle.

The brake is provided with a manual release

lever or rod. When the motor is off and the load

is to be moved without energizing the motor,

the manual release lever or rod should be

used. This removes the holding torque from the

motor shaft, allowing it to be rotated by hand,

however drag may be noted. The brake will

remain in the manual release position until the

release lever or rod is returned manually to its

set position, or until the brake is re-energized

electrically and the release lever or rod returns

to its set position automatically.

Note:

Fan-guard mounted brakes requiring

IP54 & IP55 protection may require additional

sealing measures beyond seals provided with

this brake. Pressurized sprays aimed at the

fan and brake hub surfaces can result in fluid

migration along the motor shaft and keyway,

and into the brake. The use of an appropriate

sealant such as

RTV

or a

forsheda

seal is

advised.

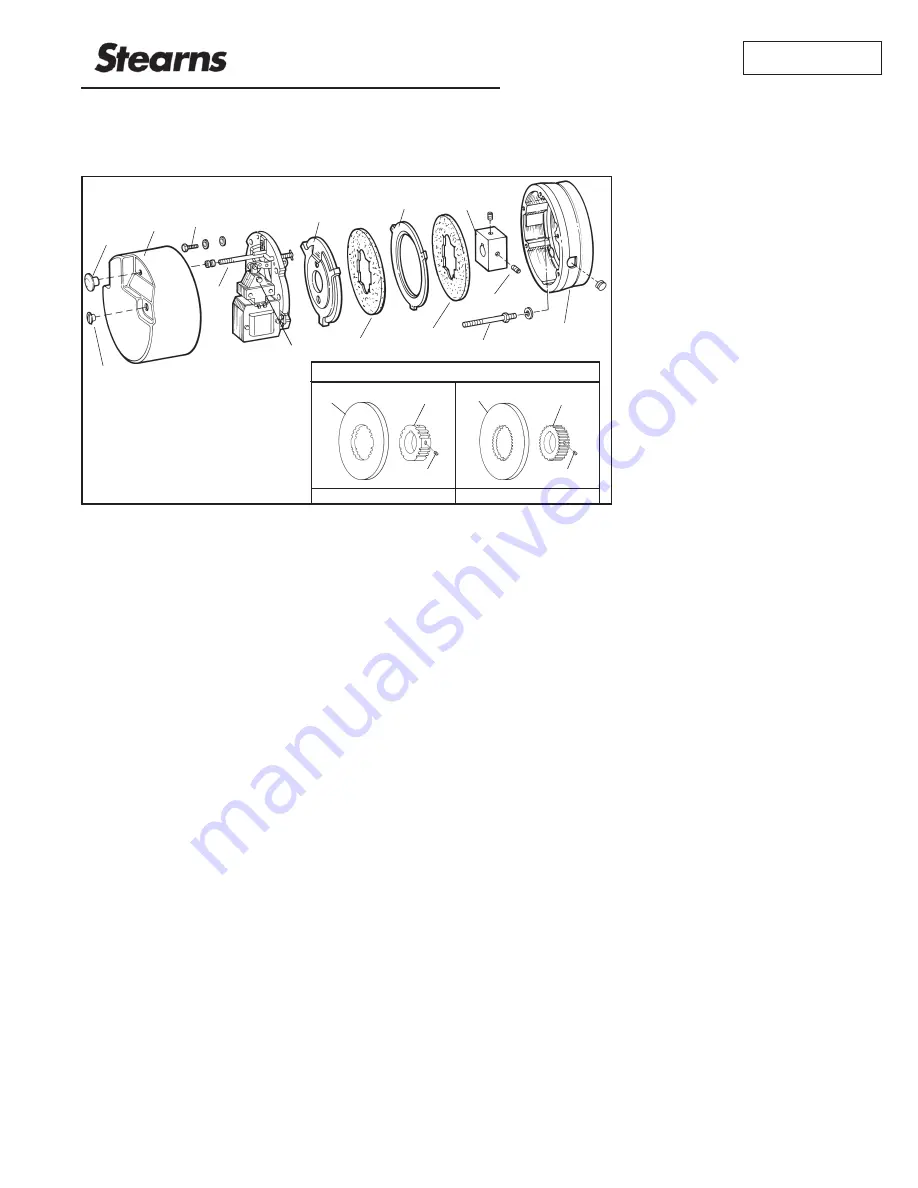

I. Installation Procedure - 87,000; 87,100;

87,400 and 87,600

A. Remove manual release knob (148) (on

pull type), housing nuts (15) and housing

(7). Housings equipped with side manual

release do not have release knob.

B. Depress solenoid plunger (29) and pull

release rod (146) back to lock brake

mechanism in manual release position or

wire tie plunger (29) to frame (79). The

87,600 Series Brake, brakes with optional

deadman manual release and brakes with

optional side manual release, the plunger

must be wire tied to the frame.

C. Remove entire support plate assembly

(142) by evenly unscrewing screw (142S).

Remove screws, conical spring washers,

and flat washers if supplied.

D. Remove pressure plate (5), friction disc (4),

and stationary disc (3).

Note 1

: Brakes with a single friction disc do

not have stationary discs. Vertically mounted

brakes will have special pins which hold spacer

springs and, in some cases, spring washers

except one-disc vertical below. Note color

coded sequence of springs and location of

washers, if used, or refer to Instruction Sheet

P/N 8-078-937-05 (Sheet 301.3) for proper

assembly of vertical mounting components.

E. Attach endplate (2) to NEMA C-face of

motor using four 1/2” diameter socket

head cap screws (not supplied) torque per

manufacturer’s specifications. (Head of

cap screws must not project above friction

surface.) If foot mounted, secure foot

mounting bracket to foundation. The use

of dowels to insure permanent alignment

is recommended. Foot, machine or C-face

mounted brakes must be carefully aligned

within .004” on concentricity and face

runout. Shaft runout should be within .002”

T.I.R. Maximum permissible shaft endfloat

is .020”.

Note 2

: If motor is to be ceiling mounted after

assembly, entire brake will have to be rotated

180° or “upside down” so it will be positioned

with solenoid plunger (29) above frame when

final assembly is mounted on ceiling. Similarly,

®

Spring-Set Disc Brakes

P/N 8-078-927-00

effective 07/14/2017

Figure 1

2

150

16S

16

3

4

4

29

5

146

142S

7

15

148

Splined Configuration

16S

16S

16B

16A

4B

4A

16 tooth

3.12 diameter

24 tooth

4.24 diameter