19

Accumulator tank capacity

NOTE:

The heat can be supplied for example

by an accumulator tank. The following applies

as a reference for the minimum storage boiler

content:

: Accumulator tank capacity in L

: Nominal heat output in kW

: Burning period in h

: Heating load of the premises in kW

: Minimum heat output in kW

Heating boilers using several allowable fuels

should have the tank size based on the fuel

that requires the largest accumulator tank.

The accumulator tank is not necessary when

the required volume is less than 300 l.

Transportation and storage

The manufacturer handles the boiler that is

on a palette and secured against shifting

(with screws). The boiler may not be

transported in a different position than on its

base.

At least regular storage conditions shall be

ensured

during

boiler

storage

and

transportation (non - aggressive environment,

air humidity lower than 75 %, temperature

range from 5 °C to 55 °C, low dustiness and

preventing influence of biological factors).

The force may not be applied on the boiler

coverings and panel during storage and

transportation.

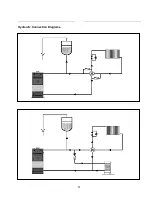

Fig. 08

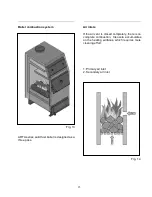

Fig. 09

Summary of Contents for ARTA series

Page 1: ...REV 01 2012 122088 ...

Page 5: ...5 Boiler dimensions ...

Page 6: ...6 Boiler packaging ...

Page 7: ...7 Technical parameters ...

Page 22: ...22 Hydraulic Connection Diagrams ...

Page 24: ...24 ARTA boiler parts ...

Page 25: ...25 ARTA boiler spare parts lists ...

Page 26: ...26 ...

Page 27: ...27 Troubleshooting ...

Page 28: ...28 NOTES ...