21

ADJUSTMENTS

The Sanding Drum is aligned parallel with the table and

completely adjusted at the factory during assembly.

However, due to stresses that occur to the unit during

shipping. It is recommended that you adjust or align

your sander using the following procedures to return it

to optimal working conditions. Do not attempt to use

the sander until you have performed all of the adjust-

ments in this section.

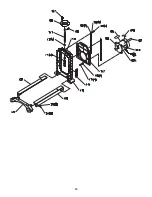

SANDING DRUM ALIGNMENT

The tightness of the Elevation Tension Adjustment

Screws needs to be adjusted to allow for smooth height

adjustments while still ensuring a tight enough fit as to

limit deflection of the drum. Too tight a fit will result in

difficulty in making height adjustments. Too loose a fit

will cause the drum to deflect excessively. To adjust:

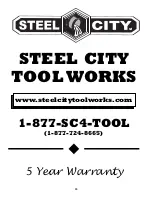

1.

Loosen the locknuts (not shown) on the opposite

end of the Elevation Tension Adjustment Screws

(A).

SEE FIG 5.

MAKE CERTAIN THAT THE SANDER IS DISCON-

NECTED FROM THE POWER SOURCE.

WARNING

!

Fig. 5

A

2.

Loosen or tighten each screw as required. Make

adjustment in 1/4 turn increments until the desired

fit is achieved.

3.

Retighten the locknuts loosened in step 1 to secure

the tension screws in position.

4.

Place a block of wood at the left side of the sander

between the drum and the conveyor belt. We will

call this Measurement A.

SEE FIG. 6.

Fig. 6

NOTE:

The abrasive strip must

NOT

be on the drum

when performing this step.

5.

Crank the handwheel counterclockwise to lower the

drum until it just touches the block of wood

6.

Using a feeler gauge, check and see the clearance

between the block of wood and the drum.

7.

Without raising or lowering the drum, slide the block

of wood over to the right side of the sander and,

again, using a feeler gauge, check the clearance

between the drum and the block of wood. This is

Measurement B. The difference between the meas-

urement A and Measurement B should be .010 or

less. If this is the case, no further adjustment is

necessary. Otherwise,

If Measurement A is greater than Measurement B by

.020 or less:

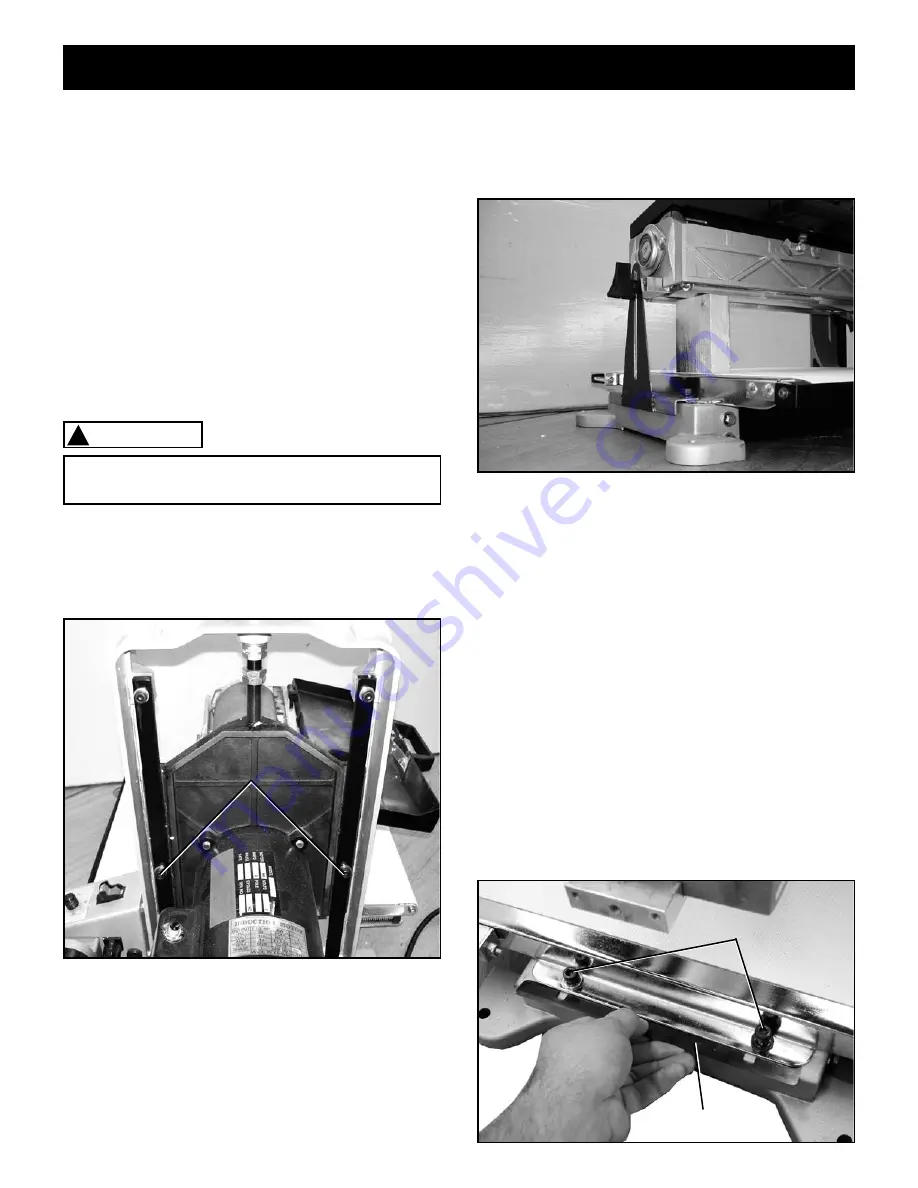

1.

Loosen the two outboard conveyor table mounting

bolts (A)

SEE FIG 7.

Fig. 7

B

A

Summary of Contents for 55210

Page 27: ...27 N NOTES N ...

Page 28: ...28 PARTS ...

Page 30: ...30 ...

Page 32: ...32 ...

Page 36: ......