22

2.

Slide one(or both, depending on how much the two

measurements are off) of the .010 shims (B) under

the edge of the conveyor belt as shown in

FIG 7.

3.

Recheck Measurement A and Measurement B

again. Confirm that the difference between the two

Measurements is less than .010.

If Measurement A is greater that Measurement B by

more than .020 OR If Measurement B is greater than

Measurement A:

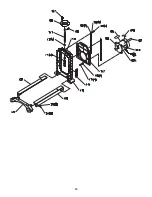

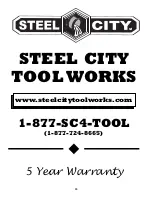

1. Loosen the two front adjustment bolts (A) and the

two rear adjustment bolts (B) slightly. This will

allow the entire drum assembly to pivot.

SEE

FIGS. 8 and 9.

Fig. 8

Fig. 9

A

B

2.

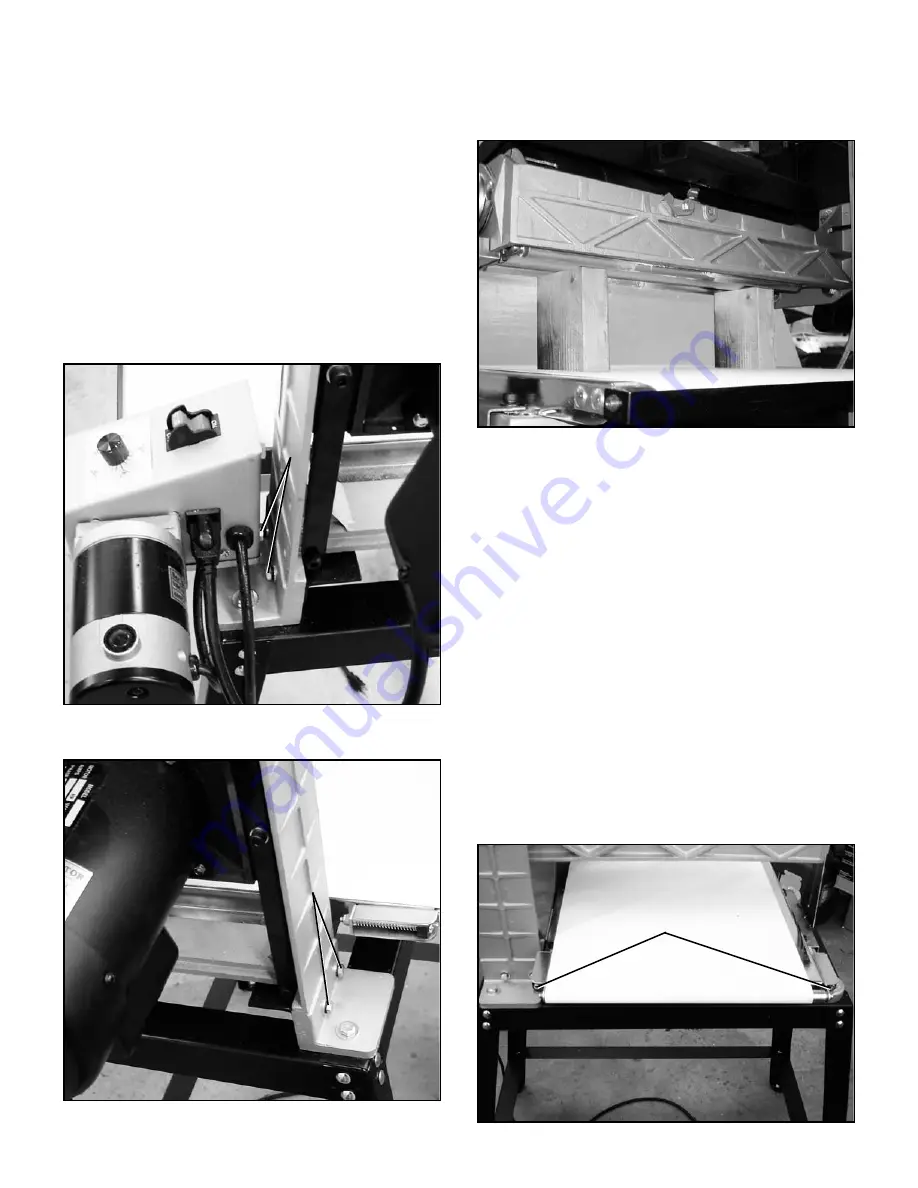

Using two wood blocks of

IDENTICAL

height, place

one at Measurement A and one at Measurement B.

SEE FIG. 10.

Fig. 10

MEASUREMENT

A

MEASUREMENT

B

3.

Crank the handwheel counterclockwise to lower the

drum until it touches both wood blocks.

4.

Retighten the bolts loosened in step 1.

5.

Using one woodblock and a feeler gauge, recheck

both Measurements A and B. Confirm that the dif-

ference between the two is less than .010

CONVEYOR FEED BELT

TRACKING ADJUSTMENT

Occasional adjustment of the conveyor feed belt track-

ing may be required due to belt stretching, normal wear

and tear, and improper tensioning. Ideally, the conveyor

feed belt should track in the center of the conveyor belt

feed table

1.

The conveyor belt feed tracking adjustment screws

(A) are located at the rear of the machine on both

the left and right side of the drum sander.

SEE FIG 11.

Fig. 11

A

Summary of Contents for 55210

Page 27: ...27 N NOTES N ...

Page 28: ...28 PARTS ...

Page 30: ...30 ...

Page 32: ...32 ...

Page 36: ......