26

TROUBLESHOOTING GUIDE

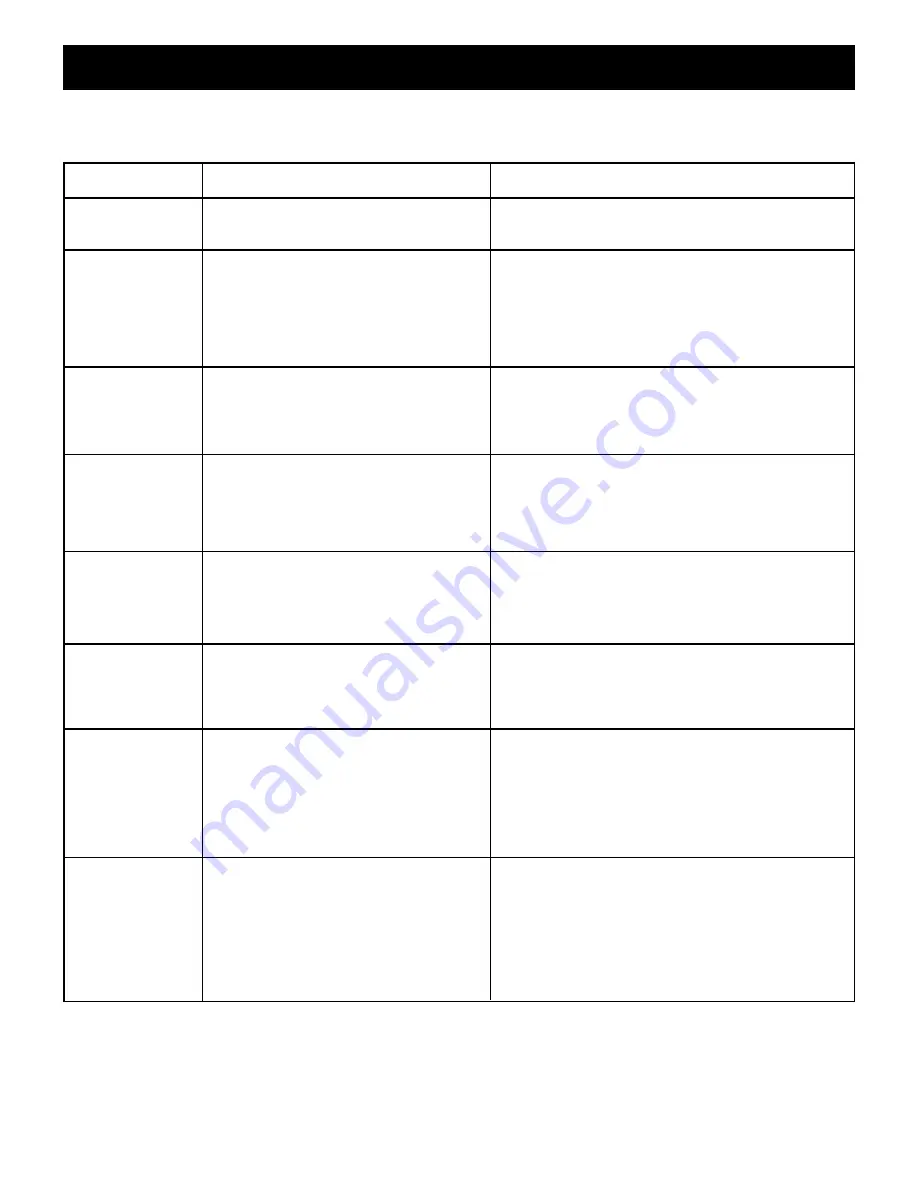

Troubleshooting Guide for Wide Drum Sander

PROBLEM

LIKELY CAUSE(S)

SOLUTION

1. Slack in abrasive strip; abrasive improperly.

1. Reattach abrasive strip. (Refer to pages 19 and 20).

1. Abrasive strip edges overlapped.

1. Reattach abrasive strip properly.

2. Abrasive loaded with resin.

2. Replace abrasive.

3. Depth of cut excessive.

3. Try coarser grit - limit depth of cut.

4. Feed rate too slow.

4. Increase feed rate.

1. Shaft coupling loose.

1. See Authorized Service Center.

1. Belt tension loose.

1. Adjust belt tension.

2. Reduce depth of cut.

3. Reduce feed rate.

1. Feed rate excessive.

1. Reduce feed rate.

2. Dirty/worn conveyor belt.

2. Replace/clean feed belt.

1. Uneven feed rate.

1. Check for belt/gear slipping on feed drive belt.

2. Motor stalls on conveyor feed drive.

2. Adjust belt tension.

1. Sanding bed flexing.

1. Reduce depth of cut.

2. Sander vibration.

2. Reduce feed rate.

3. Drum dirty - out of balance.

3. Check for: Loose bolts, loose shaft coupling set screws;

Clean sanding drum if out of balance. (Have service

performed by a Factory or Authorized Service Center.)

1. Excessive combined total load on sanding

1. Allow motor to cool and reset overload button.

drum and motor.

2. Low line voltage/extension cord gage too

2. Reduce feed rate and/or depth of cut. Limit length of cord

small.

and gage of wire 50’ or less, 12 gage minimum.

3. Excessive length or inadequate gage

3. If overload continues to trip, see Factory or Authorized

extension cord.

Service Center.

Abrasive strip comes

loose from clips.

Sanding drum feed

belt - runs

intermittently.

Stock slips on

sanding drum

feed belt.

Non-evenly

spaced ripples

on stock.

Evenly spaced

ripples on stock.

Motor overload

trips or shop wiring

circuit breaker

trips.

Sanding drum feed

belt slips on drive

rollers.

Wood burned during

sanding.

Summary of Contents for 55210

Page 27: ...27 N NOTES N ...

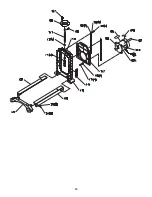

Page 28: ...28 PARTS ...

Page 30: ...30 ...

Page 32: ...32 ...

Page 36: ......