17

ADJUSTMENTS

CONVEYOR BELT TENSION

AND TRACKING

The conveyor belt may slide to the right or left during

operations if the tension of the conveyor belt is too

loose or too tight. To adjust, follow these procedures:

1.

While the unit is running, turn the adjustment bolts

(A) on either side of the conveyor table.

SEE FIG. 7.

2.

The conveyor belt should run at the center of the

conveyor table, and should be tensioned so that

there is good traction during stock feeding.

Fig. 7

A

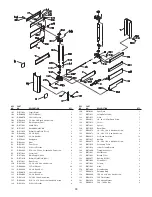

SANDING DRUM DRIVE BELTS

Both sanding drums are driven by two belts and pow-

ered by one motor. If the belt becomes too loose, follow

these procedures:

1.

Remove the right end guard, and the front guard.

2.

Adjust the height position of the motor by turning

the M12 nuts (A) located on the height adjustment

bolt.

SEE FIG. 8.

3.

If the motor becomes damaged and needs to be

replaced, remove the bolts (B) on the bottom of the

motor base plate (C), and remove the entire motor

assembly.

Fig. 8

A

B

C

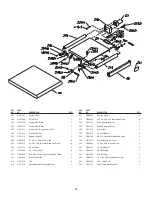

REPLACING THE CONVEYOR BELT

If the conveyor belt gets too worn out, the material

being fed will not produce satisfactory results. The

conveyor belt will need to be replaced for ideal results.

TO REPLACE THE CONVEYOR BELT:

1.

Remove the guards at both ends of the sander.

2.

The four cap screws (A) at the bottom of the feed

table assembly must be removed.

SEE FIG. 9.

Fig. 9

3.

You can now remove the feed table (B); this will

allow you to replace the conveyor belt (C).

B

C

A

Summary of Contents for 55220

Page 28: ......