18

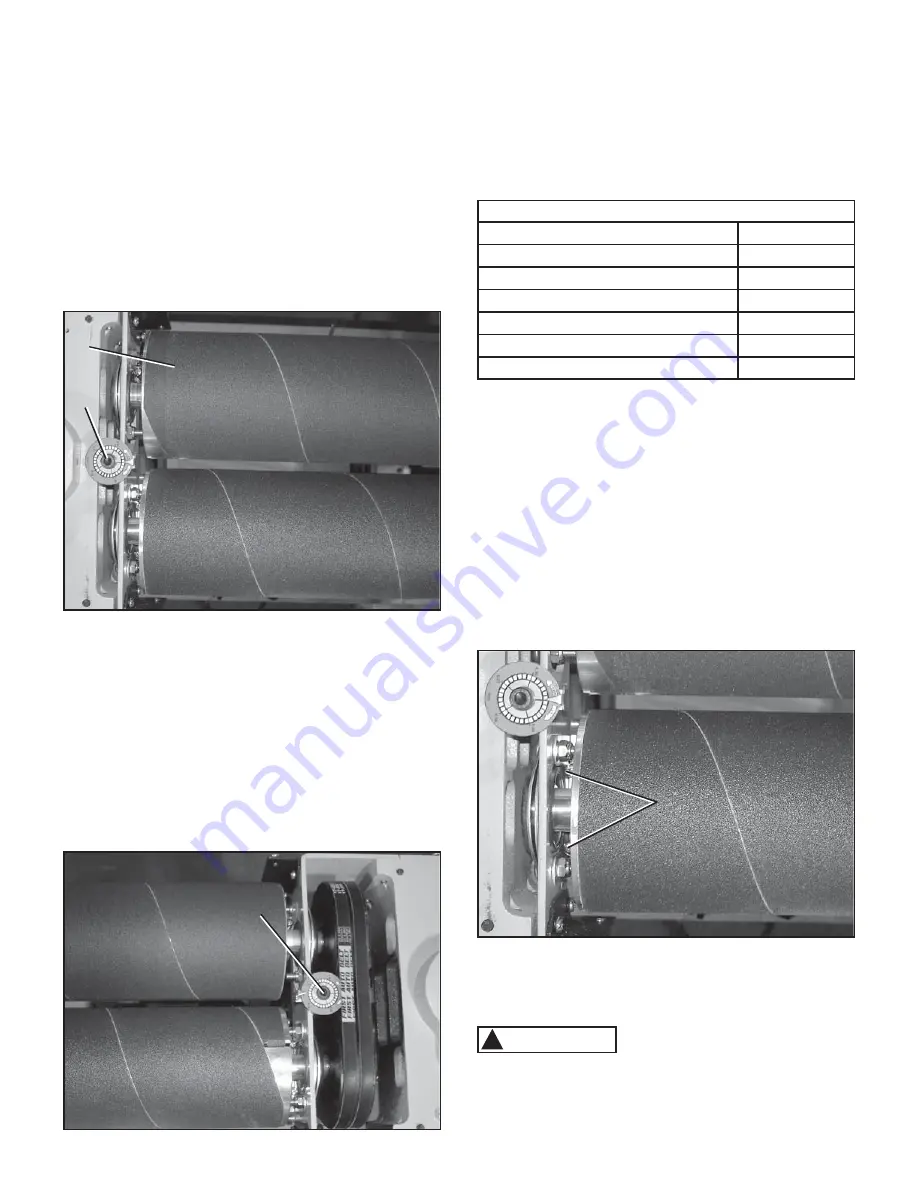

PARALLELISM ADJUSTMENT

OF SANDING DRUM

The front sanding drum has been factory adjusted and

needs no further adjustment. The rear sanding drum

must be adjusted for parallelism.

TO ADJUST, FOLLOW THESE PROCEDURES:

1.

Adjust using the cap screws (A) on either end of the

sanding drums (B), using a T-wrench. Turning the

cap screw clockwise will raise the drum while turn-

ing it counterclockwise will lower the drum.

SEE FIG. 10.

2.

Make adjustments to both sides of the rear drum if

necessary, until it is parallel with the front drum.

Fig. 10

A

B

DRUM HEIGHT

When using different abrasive grits on the drums, the

height of the drums from the workpiece must vary. To

achieve this, the back drum (which should always have

the finer grit) has been designed for easy adjustment.

1.

Rotate the cap screw (A) to the desired measure-

ment.

SEE FIG. 11.

2.

Repeat this dial setting on the opposite end of the

drum.

NOTE:

It is important that the dial setting be

identical at both ends of the drum.

IMPORTANT:

After changing abrasive strips, always

check and, if necessary, reset the back drum height.

The chart below shows the proper settings based upon

sanding grits.

Fig. 11

A

REAR DRUM SETTING GAUGE

Front Drum Grit / Rear Drum Grit

Setting (mm)

80/100, 120/150, 120/180, 150/220

.15

80/120, 100/150, 100/180

.30

60/100, 36/38

.40

36/120

.56

36/60

.76

36/80

.93

PRESSURE ROLLERS

The pressure rollers maintain tension upon the work-

piece as it passes through the machine. The spring

tension of the pressure rollers has been factory set.

If a board refuses to pass through the machine, or the

finished surface of a board is uneven, the spring ten-

sion of the pressure rollers may need adjusting.

1.

Turn the Phillips head screws (A), clockwise to

increase the roller pressure on the workpiece; or

counterclockwise to decrease the pressure.

SEE FIG. 12.

Fig. 12

A

2.

Repeat this same adjustment at the opposite end of

the roller to maintain parallel.

3.

Repeat procedure for the other pressure roller.

Do not overtighten the adjusting screw, as excess

roller pressure will prevent the workpiece from

passing through the machine, and may cause the

conveyor belt to stop.

CAUTION

!

Summary of Contents for 55220

Page 28: ......