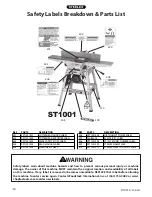

ST1001 6" Jointer

-27-

Figure 40.

Cutterhead profile diagram.

������

������

�����

��������

���

����

�����

�������

The Model ST1001 comes with both jack screws and

springs inside the cutterhead to provide two options

for adjusting the knives (see

Figure 40

).

Note:

Only

one of these options is needed to set the knives—see

Step 7 on Page 28

for clarification.

Figure 39.

Using knife setting jig to set knife height.

Knife Setting Jig Method:

Both tables are lowered to

fit the jig on the cutterhead, as shown in

Figure 39

,

and the knife heights are set to just touch the middle

pad of the jig.

The knife setting jig makes it easy to ensure that the

knives project out of the cutterhead evenly. After

using the knife setting jig to set the knives, you have

to re-adjust the outfeed table height to ensure that it

is even with the knives at their highest point of rota-

tion. If you use the positive stops on the tables, reset

them before operation.

Adjusting/Replacing

Knives

Setting the knives correctly is crucial to the proper

operation of the jointer and is very important in

keeping the knives sharp. If one knife is higher than

the others, it will do the majority of the work, and

thus, dull much faster than the others.

There are two options for setting the knives—the

straightedge method and the knife setting jig meth-

od. Each option has advantages and disadvantages

and the correct one for you will become a matter of

personal preference.

Straightedge Method:

A high quality straightedge

is held flat against the outfeed table and the knife

heights are set to the bottom of the straightedge, as

shown in

Figure 37

.

When using a straightedge to set the knives, you are

assured that the knives are even with the outfeed

table in their highest point of rotation—even if the

cutterhead is not parallel with the outfeed table.

To use the straightedge method, disconnect power

and place the straightedge on the outfeed table

so it hangs over the cutterhead. Lower the outfeed

table until the straightedge is 0.062" (1⁄16") above

the cutterhead body, as determined by using a feeler

gauge or combination of feeler gauges between the

bottom of the straightedge and the cutterhead body

(see

Figure 38

). Tighten the outfeed table lock.

������������

�������������

��������

�

�

��

��

������������

Figure 38.

Using feeler gauge to set outfeed table

height.

Now, set the knife heights to the new outfeed table

height. (As long as the outfeed table remains locked,

that part of the procedure will not have to be repeat-

ed the next time you replace or adjust the knives.)

Summary of Contents for ST1001

Page 2: ......

Page 36: ...34 ST1001 6 Jointer ST1001 Wiring Diagram...

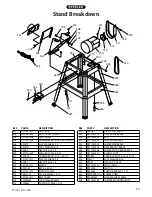

Page 37: ...ST1001 6 Jointer 35 Jointer Breakdown...

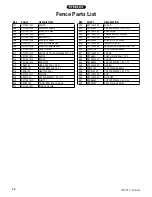

Page 39: ...ST1001 6 Jointer 37 Fence Breakdown...

Page 44: ......

Page 47: ......

Page 48: ......