-30-

ST1006/ST1011 8" Jointer (Mfd. Since 3/16)

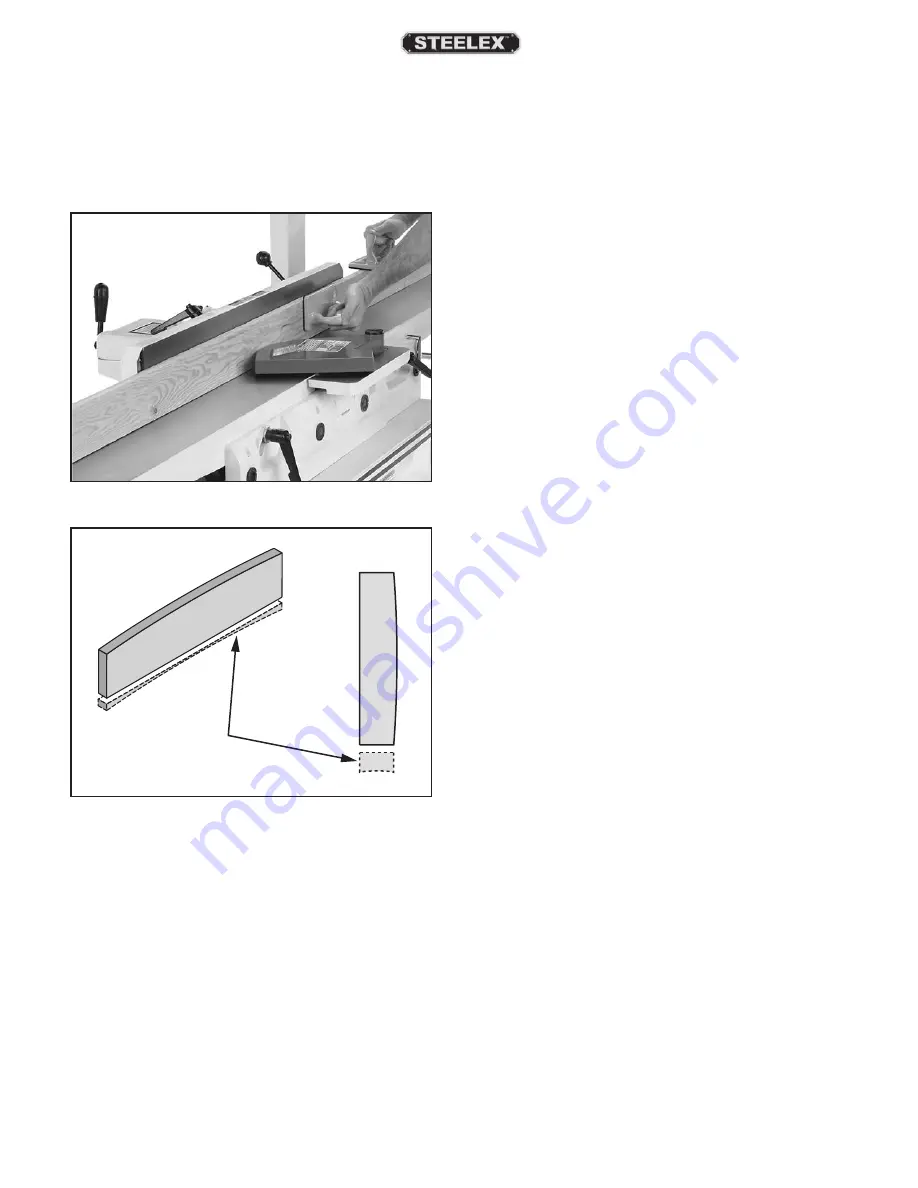

Edge Jointing

Figure 36. Example of edge jointing operation.

Removed

Surface

Figure 37. Illustration of edge jointing results.

The purpose of edge jointing is to produce a finished,

flat-edged surface that is suitable for joinery or finish-

ing, as shown in Figures 36–37. It is also a necessary

step when squaring rough or warped stock.

To edge joint on jointer:

1. Inspect stock to ensure it is safe and suitable

for the operation (see Stock Inspection &

Requirements section).

2. Set infeed table height to desired cutting depth

for each pass.

IMPORTANT: For safety reasons, cutting depth

should never exceed

1

⁄

8

" per pass.

3. Set fence to 90˚.

4. Start jointer.

5. Place workpiece firmly against fence and infeed

table.

IMPORTANT: To ensure workpiece remains

stable during cut, concave sides of workpiece

must face toward table and fence.

6. Feed workpiece completely across cutterhead

while keeping it firmly against fence and tables

during the entire cut.

IMPORTANT: Keep hands at least 4" away from

cutterhead during the entire cut. Instead of

allowing a hand to pass directly over cutterhead,

lift it up and over cutterhead, and safely repo-

sition it on the outfeed side to continue sup-

porting workpiece. Use push blocks whenever

practical to further reduce risk of accidental

hand contact with cutterhead.

7. Repeat

Step 6 until the entire edge is flat.

Tip:

When squaring up stock, cut opposite edge

of workpiece with a table saw instead of the

jointer—otherwise, both edges of workpiece will

not be parallel with each other.