-32-

ST1006/ST1011 8" Jointer (Mfd. Since 3/16)

Rabbet Cutting

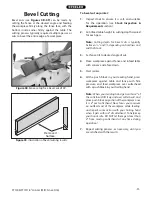

The purpose of rabbet cutting (see Figures

40

–

42

)

is to remove a section of the workpiece edge, as

shown below. When combined with another rabbet

cut edge, the rabbet joints create a simple, yet strong

method of joining stock.

Removed

Surface

Figure 42. Illustration of rabbet cutting effects and

a few sample joints.

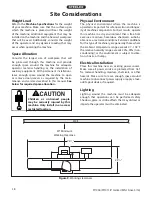

Figure 40. Typical rabbet cutting operation.

Figure 41. Completed rabbet cutting operation.

When cutterhead guard is removed, attempt-

ing any other cut besides a rabbet direct-

ly exposes operator to moving cutterhead.

ALWAYS replace cutterhead guard after rabbet

cutting!

To rabbet cut on jointer:

1.

Inspect stock to ensure it is safe and suitable

for the operation (see Stock Inspection &

Requirements section).

2.

Set infeed table height to desired cutting depth

for each pass.

IMPORTANT:

For safety reasons, cutting depth

should never exceed 1⁄8" per pass.

3.

Remove cutterhead guard.

4.

Set fence to 90˚ and near front of jointer, so

amount of exposed cutterhead in front of fence

matches size of desired rabbet.

5.

Start jointer.

6.

Place workpiece firmly against fence and infeed

table.

IMPORTANT:

To ensure workpiece remains sta-

ble during cut, concave sides of workpiece must

face toward table and fence.

7.

Feed workpiece completely across cutterhead

while keeping it firmly against fence and tables

during entire cut.

IMPORTANT: Keep hands at least 4" away from

cutterhead during the entire cut. Instead of

allowing a hand to pass directly over cutterhead,

lift it up and over cutterhead, and safely reposi-

tion it on the outfeed side to continue support-

ing workpiece. Use push blocks whenever prac-

tical to further reduce risk of accidental hand

contact with cutterhead.

8.

Repeat Step 7 until rabbet is cut to depth.