-40-

ST1006/ST1011 8" Jointer (Mfd. Since 3/16)

7. Adjusting the knife heights:

Jack Screws: Using a 3mm hex wrench, find

the jack screws through the access holes in the

cutterhead (see Figure 58) and rotate the jack

screws to raise or lower the knife. When the knife

is set correctly, it will barely touch the bottom

of the straightedge or the knife setting jig mid-

dle pad (depending on which method you are

using). Snug the gib bolts tight enough to just

hold the knife in place. Repeat on the other side

of the cutterhead, then repeat Steps 5–7 with

the rest of the knives.

Figure 52. Jack screw access hole.

Springs: Push the knife down with the straight-

edge or middle pad of the knife setting jig, keep-

ing the straightedge flat against the outfeed

table or the knife setting jig feet evenly against

the cutterhead (depending on which method

you are using). Tighten the gib bolts just tight

enough to hold the knife in place. Repeat on the

other side of the cutterhead, then repeat Steps

5–7 with the rest of the knives.

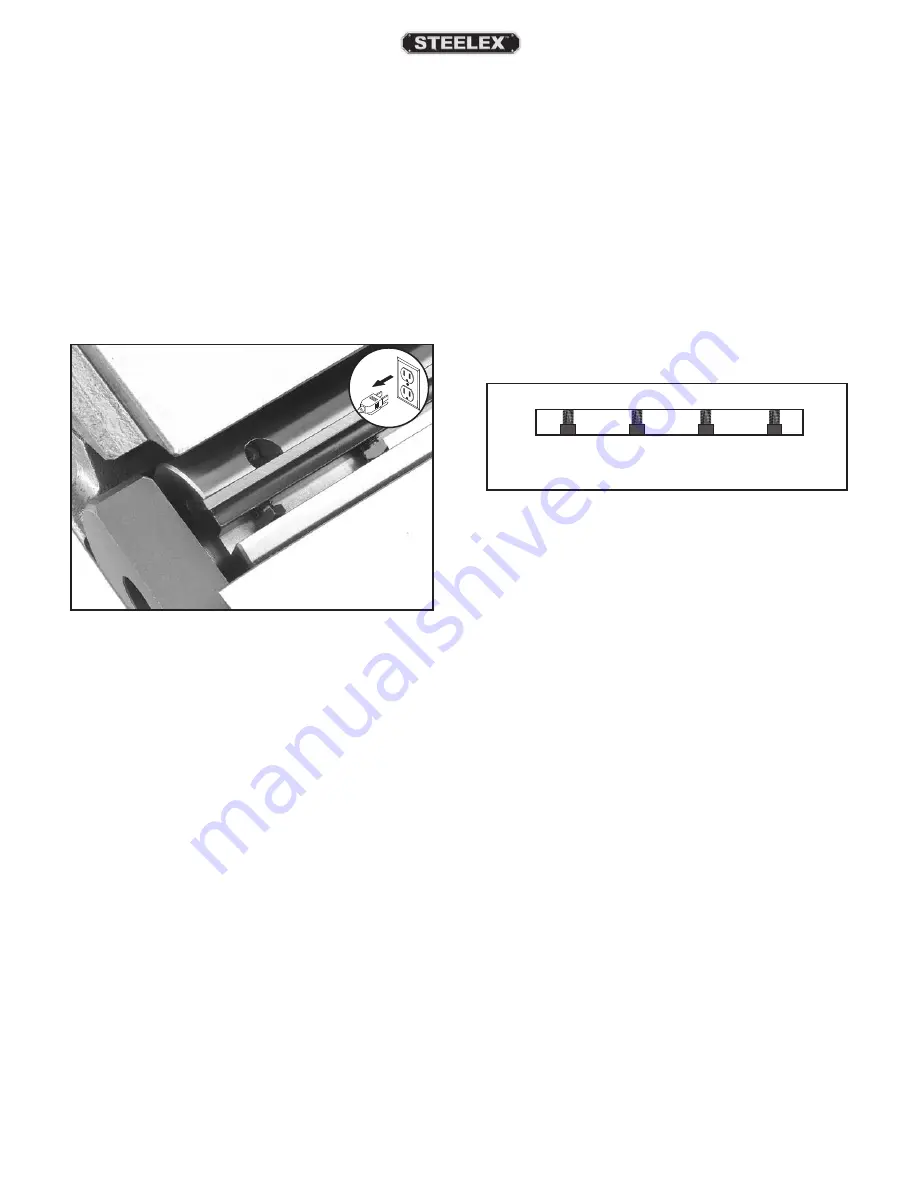

8. Rotate the cutterhead to the first knife you start-

ed with. Slightly tighten all the gib bolts, starting

at the ends and working your way to the middle

by alternating left and right (see Figure 53).

Repeat this step on the rest of the knives.

9. Repeat

Step 8.

10. Repeat Step 8, but final tighten each gib bolt.

11. If you used the knife setting jig to set the

knife heights, use the straightedge to adjust

the outfeed table height evenly with the knives

at top dead center (the highest point in their

rotation). If you used the straightedge to set the

knife heights, skip to the next step.

12. Replace the cutterhead guard and the close the

back cover.

Figure 53. Gib bolt tightening sequence.

1

4

2

3