ST1013 12" Jointer (Mfd. Since 3/16)

-27-

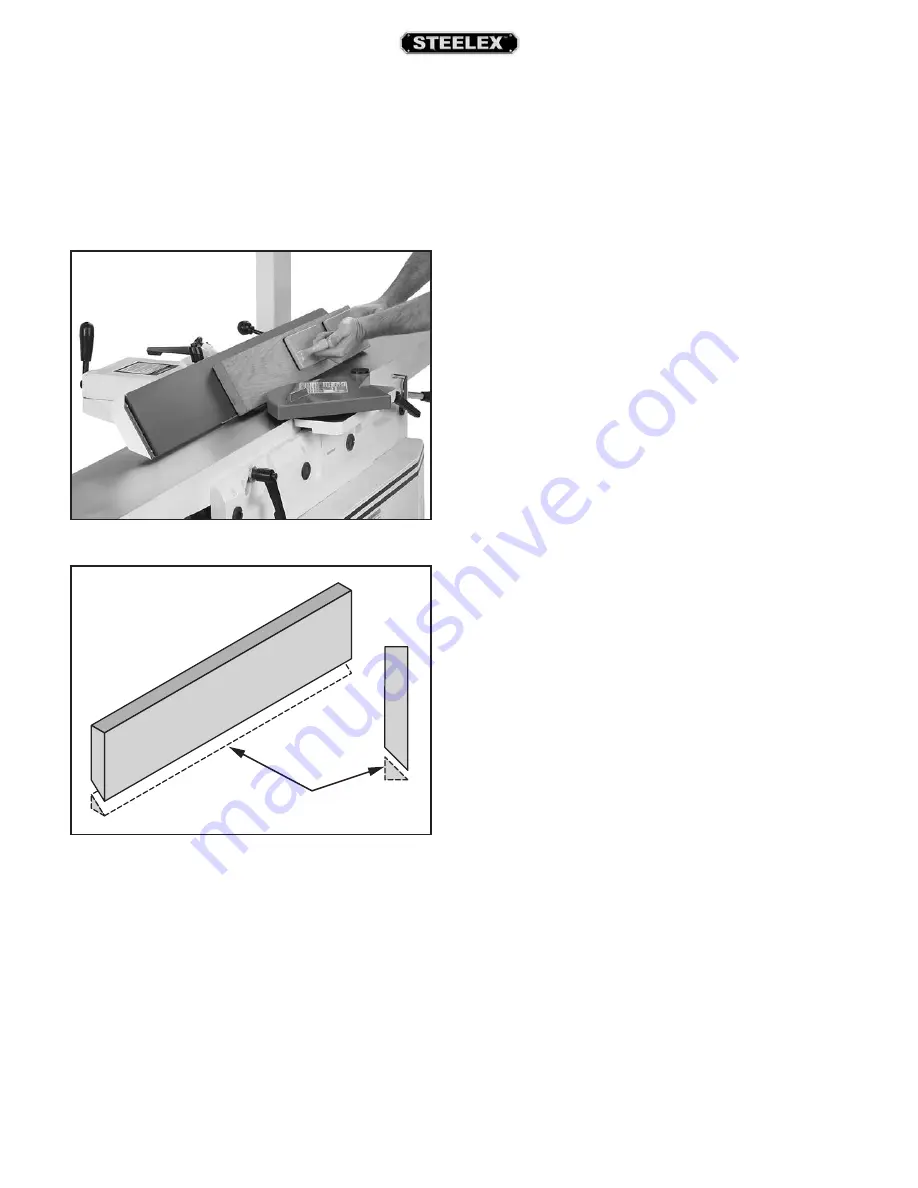

Bevel cuts (see Figures 32–33) can be made by

setting the fence at the desired angle and feeding

the workpiece firmly along the fence face, with the

bottom inside corner firmly against the table. The

cutting process typically requires multiple passes or

cuts to bevel the entire edge of a workpiece.

Bevel Cutting

Figure 32. Fence setup for a bevel cut of 45°.

Removed

Surface

Figure 33. Illustration of bevel cutting results.

To bevel cut on jointer:

1. Inspect stock to ensure it is safe and suitable

for the operation (see Stock Inspection &

Requirements section).

2. Set

infeed table height to cutting depth desired

for each pass.

Note:

Cutting depth for bevel cuts is typically

between

1

⁄

16

" and

1

⁄

8

", depending on hardness and

width of stock.

3. Set fence tilt to desired angle of cut.

4. Place workpiece against fence and infeed table

with concave side face down.

5. Start jointer.

6. With

a push block in your leading hand, press

workpiece against table and fence with firm

pressure, and feed workpiece over cutterhead

with a push block in your trailing hand.

Note:

When your leading hand gets within 4" of

the cutterhead, lift it up and over cutterhead, and

place push block on portion of the workpiece once

it is 4" past cutterhead. Now, focus your pressure

on outfeed end of the workpiece while feeding,

and repeat same action with your trailing hand

when it gets within 4" of cutterhead. To help keep

your hands safe, DO NOT let them get closer than

4" from moving cutterhead at any time during

operation!

7. Repeat cutting process, as necessary, until you

are satisfied with the results.