ST1013 12" Jointer (Mfd. Since 3/16)

-37-

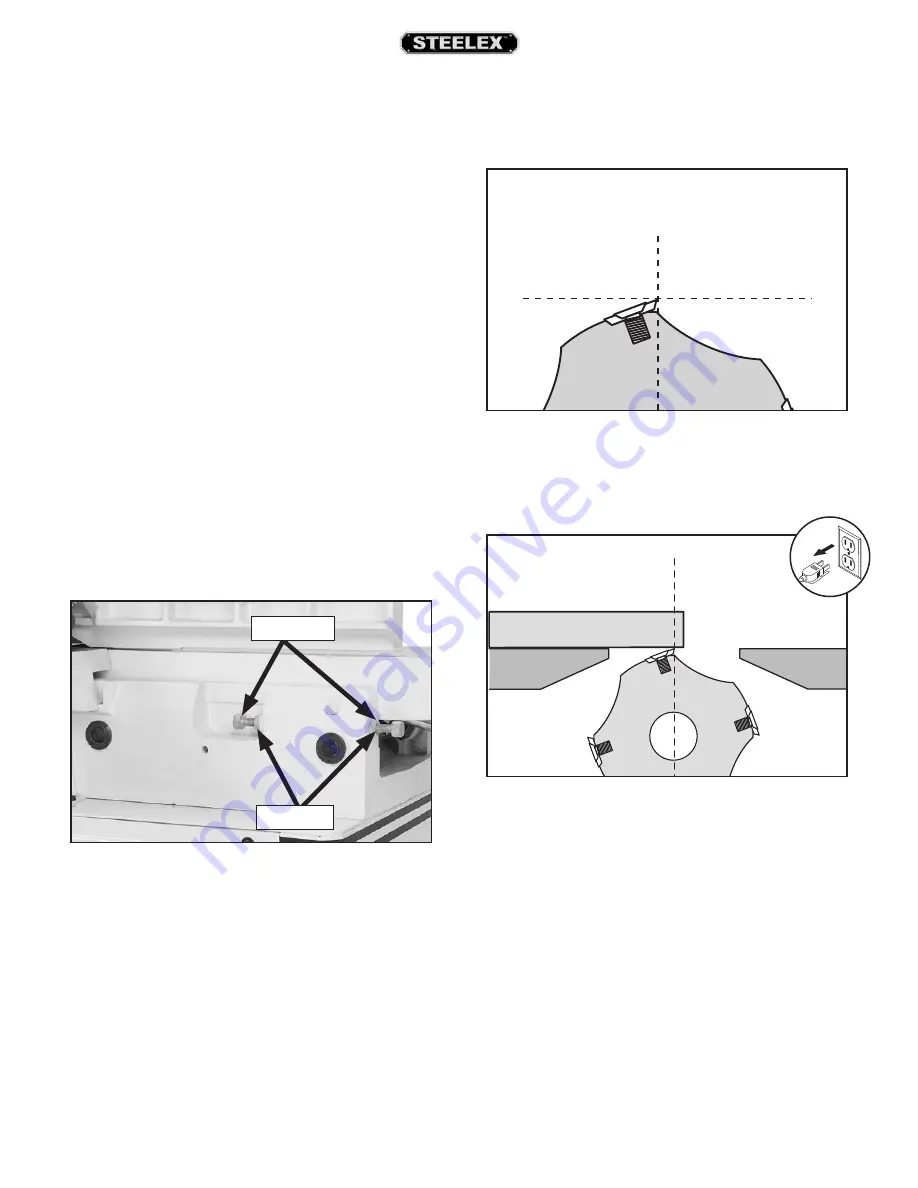

Setting Outfeed Table

Height

The outfeed table height must be even with the

top of the cutterhead inserts. If the outfeed table is

set too low, there will be snipe. If the outfeed table

is set too high, the workpiece will hit the edge of

the outfeed table during operation, increasing the

chance of kickback.

Tools Needed

Qty

Straightedge .......................................................................... 1

Open-End Wrench 16mm.................................................. 1

To set outfeed table height:

1. DISCONNECT MACHINE FROM POWER!

2. Remove cutterhead guard, fence, and cabinet

rear access panel.

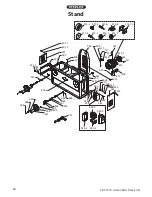

Figure 50. Outfeed table positive stop bolts.

Stop Bolts

Jam Nuts

5. Use motor pulley to rotate cutterhead until one

of the inserts is at top dead center (its highest

point during rotation), as illustrated in Figures

51–52.

3. Loosen outfeed table lock located at front of

machine, and loosen jam nuts and positive stop

bolts located at back of machine just behind

outfeed table (see Figure 50).

6. Use outfeed table adjustment lever to set outfeed

table so that insert barely touches straightedge,

as illustrated in Figure 52.

Figure 52. Using straightedge to check outfeed

table height.

Straightedge

Outfeed

Infeed

7. Tighten outfeed table lock located at front of

machine, and tighten outfeed positive stop

bolts and jam nuts located at back of machine

(see Figure 50) so that outfeed table will not

move during operation.

8. Re-install cutterhead guard, fence, and cabinet

rear access panel.

4. Place straightedge on outfeed table so it extends

over cutterhead.

Figure 51. Insert at top dead center.

Bottom Dead

Center

Top Dead

Center