-38-

ST1013 12" Jointer (Mfd. Since 3/16)

Setting Infeed Table

Height

The infeed table on the Model ST1013 has positive

stop bolts that, when properly set up, allow the oper-

ator to quickly adjust the infeed table between finish/

final cuts and shaping/heavy cuts.

We recommend setting the minimum depth of cut to

1

/

32

" and the maximum depth of cut to

1

/

8

" for most

operations. DO NOT exceed

1

⁄

8

" cut per pass on this

machine or kickback and serious injury may occur!

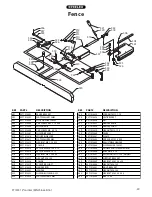

Each positive stop bolt (see Figure 53) controls the

top or bottom range of the table movement. The jam

nut locks the positive stop bolt in position so it will

not move during operation.

Figure 53. Positive stop bolts for infeed table.

Top Height

Bottom Height

Jam Nuts

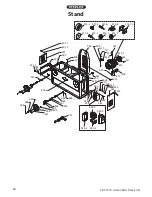

Calibrating Depth

Scale

To calibrate depth scale:

1. DISCONNECT MACHINE FROM POWER!

2. Loosen infeed table positive stop bolts (see

Figure 53).

Straightedge

Infeed

Outfeed

Figure 54. Infeed table even with outfeed table.

3. Use straightedge to help adjust infeed table

exactly even with outfeed table, as shown in

Figure 54.

Figure 55. Depth scale adjusted to “0” position.

4. Using a screwdriver, adjust scale pointer to “0”

(see Figure 55), then reset infeed table positive

stops.

The depth-of-cut scale can be calibrated or "zeroed"

to make sure the cutting depth shown on the scale

matches the actual cutting depth (per pass).

Tools Needed

Qty

Straightedge .......................................................................... 1

Phillips Screwdriver #2 ....................................................... 1