-40-

ST1013 12" Jointer (Mfd. Since 3/16)

Tensioning/Replacing

V-Belt

To ensure optimum power transmission from the

motor to the cutterhead, the belt must be in good

condition (free from cracks, fraying and wear) and

properly tensioned. As the machine is used, the belts

will slightly wear and stretch, eventually losing their

efficiency of transmitted power until they can be

retensioned.

Also, a new belt typically has a break-in period, and

should be checked/retensioned after the first 16

hours of belt life, as it will stretch and seat during this

time.

Tools Needed

Qty

Wrenches or Sockets 13mm ............................................. 2

Tensioning Belt

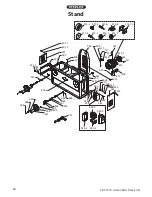

1. DISCONNECT MACHINE FROM POWER!

2. Open pulley cover.

3. Loosen fasteners on tension rod that hold motor

to bracket, as shown in Figure 60.

4. Lift motor up and slide V-belts off of motor pul-

ley and cutterhead pulley.

5. Slide new belts onto pulleys and lightly tighten

motor bracket fasteners.

Motor Pulley

Approximately

1

/

4

" Deflection

Cutterhead Pulley

Figure 61. Correct belt deflection when properly

tensioned.

Replacing Belt

1. DISCONNECT MACHINE FROM POWER!

2. Open pulley cover and loosen motor bracket

fasteners shown in Figure 60.

3. Have another person lift motor as you remove

belt and replace it with a new one. It may help

to use a 2x4 as a lever to raise motor.

4. Follow

Steps 4–6 in Tensioning Belt procedure

above to set correct belt tension.

5. Tighten motor bracket fasteners (see Figure 60)

and close pulley cover.

6. Press belt with moderate pressure in center to

check belt tension. Belt is correctly tensioned

when there is approximately

1

⁄

4

" deflection when

pushed, as shown in Figure 61.

—If there is more than 1⁄4" deflection when you

check belt tension, repeat the tensioning pro-

cedure until it is correct.

7. Tighten motor bracket fasteners (see Figure 60),

and close pulley cover.

Figure 60. Fasteners to be loosened for V-Belt

replacement.

Tension

Rod

Fasteners