D1PRO

D1 PRO 11-2011

Operators manual for D1 PRO Drilling Machine

- 8 -

4. START UP AND OPERATION

4.1 Cutters and optional equipment features.

This drilling machine’s spindle has a Weldon Shank type socket 3/4” or

19.05 mm and is specifically designed for use with milling cutters.

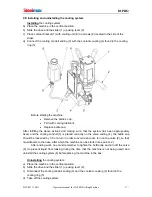

Milling cutter (2) is located inside arbor body (1) and is fastened with screws

(3). While fastening the cutter in the socket, be aware that screws should be screwed

tight so that they do not come loose. It is important to position the cutter in relation to

the socket in such a way that the flats on the cutter shank are positioned under the

fixing screws (3). Both fastening screws(3) should be used to secure the cutter. Pilot

(5) is located inside the cutter. It makes it easier to position milling cutter over the

center of a planned hole. During drilling as the cutter goes deep into steel, the pilot

moves back into the arbor body and tightens discharge spring (4). That spring ejects

slug which is a by-product of milling a hole with a center free cutter. The pilot also

allows cutting fluid to cool and lubricate the cutter from the inside.

Basically milling cutters are designed to make through holes. On occasions when

there is a need for an overlapping hole the pilot should not be used.

Drawing 2.

Principle of milling cutter’s work

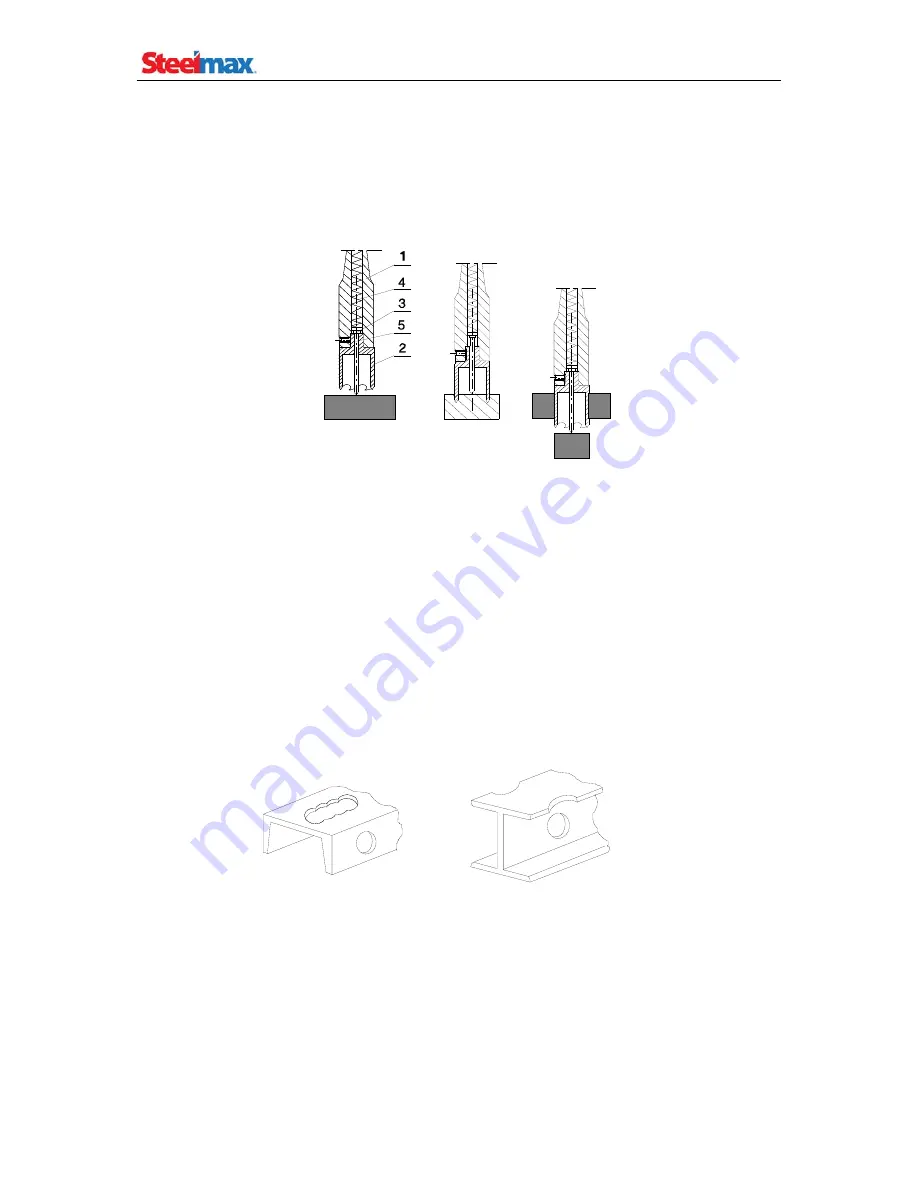

Drawing 3.

A few types of holes that can be done with a milling cutter