6

STEIN300_Hubzentriereinrichtung_HZEV_03_GB.DOC_D / 02.2020

2

Introduction

The safety of all persons who come into contact with the HZEV depends fundamentally

on knowing how the HZEV functions. Therefore:

Read these operating instructions before using the equipment for the first time.

These operating instructions contain important information which will ensure the correct,

economical and safe operation of your HZEV.

2.1

Short description

Lift centring devices are installed in the STEIN 300 Workpiece Transport System.

In conjunction with the workpiece carrier transport system, the HZEV enables the follo-

wing:

•

exact positioning of workpiece carriers (and therefore of the workpieces located on

them),

•

a further lift of the WT in the Z axis

•

workpiece carrier elevation and support while power transfer operations are carried

out on workpieces.

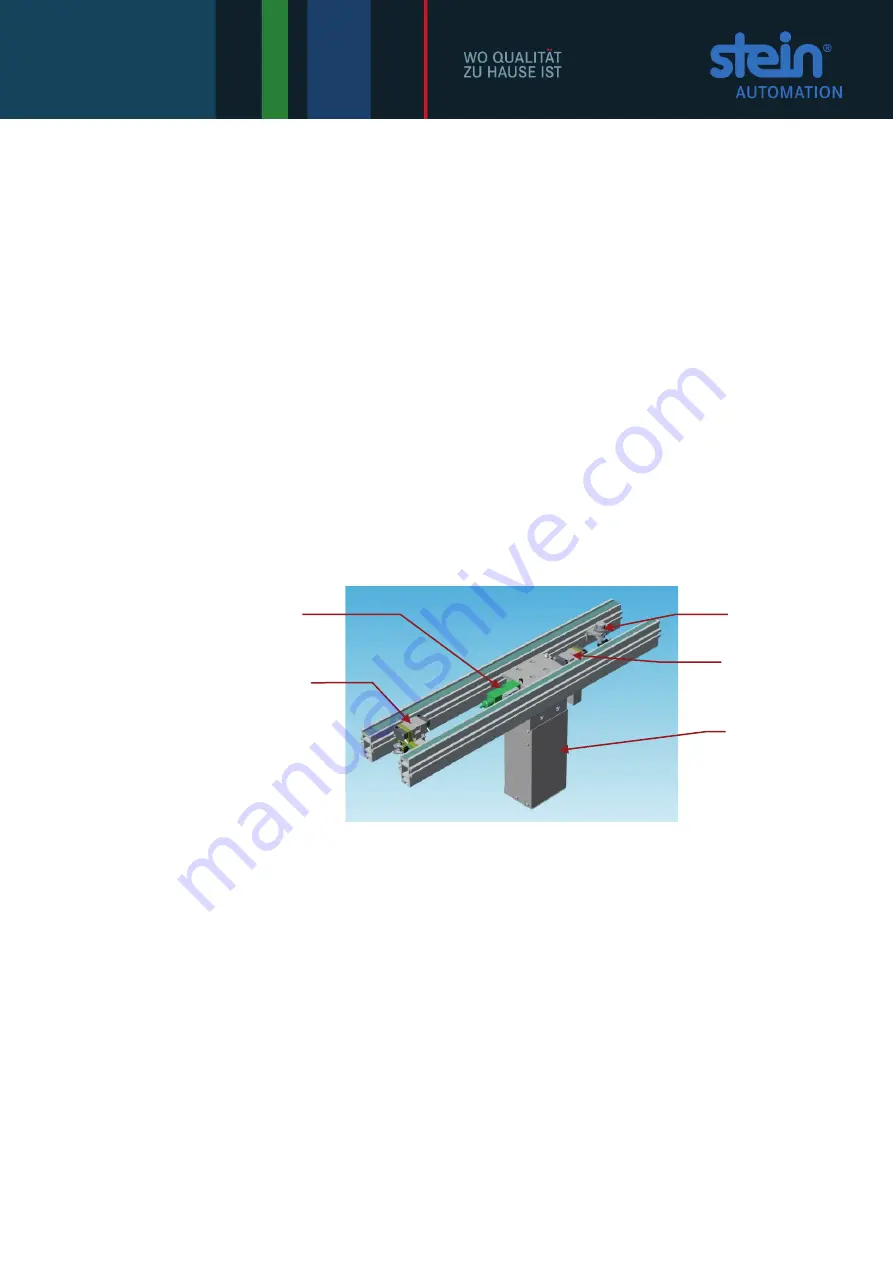

Fig. 2-1:

Lift centring device

- Components

Other advantages of these devices are that

•

the belt element is not under tension while the workpiece is being processed and

•

belt wear is reduced.

i

Please note:

From a stroke of 250mm, the WT must additionally be centred from above in the end

position by means of suitable centring pins, as otherwise the specified centring

accuracy is not given. These centring pins are not included in the scope of delivery.

Pre-stopper

Reading head

(optional)

Stopping de-

vice

HZEV

Surface

switch