19

ZTM 1250

ZTM 1250

ZTM 1250

ZTM 1250

ZTM 1250

BELT REPLACEMENT

CUTTERDECK-TIMING BELT

1. Raise the foot plate on the cutterdeck.

2. Back off nut

N

to allow for removal of timing belt.

3. Loosen the three bolts

B

locking the timing belt

idler in place.

4. Install an extension on a 3/8” drive ratchet.

Insert it in the square hole of the timing belt idler

arm and use the ratchet handle to rotate the idler

enough to remove the belt from the idler and

drive sprockets.

When handling timing belts, take care not to twist or

bend them severely. Mishandling timing belts can

break the cords in them and lead to premature failure.

5. Install the new timing belt on the sprockets.

Line up the drive sprockets so the timing

marks

T

areat 90 degrees to each other. This

puts the blades at 90 degrees to each other as

well.

6. Tighten nut

N

until the bottom of the nut is aligned

with the notch in the bracket as shown.

7. Lock the idler in place by tightening nuts

B

.

8. Start the engine and operate the deck for a few

minutes to allow the belt to run in.

9. Loosen the locking nuts

B

and allow the spring to

take up the slack.

DO NOT OVER TENSION

.

The spring will supply the correct amount of

tension as long as the idler arm is free to rotate.

Lock the idler down.

10. Check the belt after the first several hours of

operation for slack. If there is any slack, repeat

step 9.

NOTE:

Timing belts use fiberglass or Aramid fiber

cords which have very little stretch. Once properly

tensioned, no further adjustment is usually neces-

sary. It is important that there be no slack in the belt,

because any slack can allow the belt to jump teeth

on the sprockets and get the blades out of time.

Since there is no stretch in the belt, it can easily be

over tightened. The spring allows the correct

amount of tension to be applied without danger of

over tension.

T

Alignment

Notch

Summary of Contents for 442105

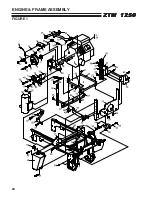

Page 26: ...24 ZTM 1250 ZTM 1250 ZTM 1250 ZTM 1250 ZTM 1250 ENGINE FRAME ASSEMBLY FIGURE 1 ...

Page 28: ...26 ZTM 1250 ZTM 1250 ZTM 1250 ZTM 1250 ZTM 1250 WHEELS BRAKES FIGURE 2 ...

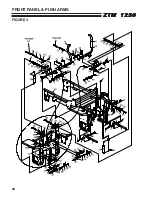

Page 30: ...28 ZTM 1250 ZTM 1250 ZTM 1250 ZTM 1250 ZTM 1250 FRONT PANEL PUSH ARMS FIGURE 3 ...

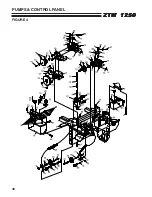

Page 32: ...30 ZTM 1250 ZTM 1250 ZTM 1250 ZTM 1250 ZTM 1250 PUMPS CONTROL PANEL FIGURE 4 ...

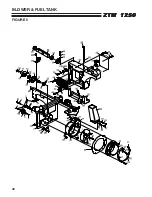

Page 34: ...32 ZTM 1250 ZTM 1250 ZTM 1250 ZTM 1250 ZTM 1250 BLOWER FUEL TANK FIGURE 5 ...

Page 36: ...34 ZTM 1250 ZTM 1250 ZTM 1250 ZTM 1250 ZTM 1250 BELTS FIGURE 6 ...

Page 38: ...36 ZTM 1250 ZTM 1250 ZTM 1250 ZTM 1250 ZTM 1250 BUMPER GRASSBOX FRAME FIGURE 7 ...

Page 40: ...38 ZTM 1250 ZTM 1250 ZTM 1250 ZTM 1250 ZTM 1250 HEAVY DUTY AIR CLEANER FIGURE 8 ...

Page 42: ...40 ZTM 1250 ZTM 1250 ZTM 1250 ZTM 1250 ZTM 1250 GRASSBOX FIGURE 9 ...

Page 44: ...42 ZTM 1250 ZTM 1250 ZTM 1250 ZTM 1250 ZTM 1250 ELECTRICAL FIGURE 10 ...

Page 46: ...44 ZTM 1250 ZTM 1250 ZTM 1250 ZTM 1250 ZTM 1250 HYDRAULICS FIGURE 11 ...

Page 48: ...46 ZTM 1250 ZTM 1250 ZTM 1250 ZTM 1250 ZTM 1250 SEAT ASSEMBLY FIGURE 12 ...

Page 50: ...48 ZTM 1250 ZTM 1250 ZTM 1250 ZTM 1250 ZTM 1250 DECALS FIGURE 13 ...

Page 52: ...50 ZTM 1250 ZTM 1250 ZTM 1250 ZTM 1250 ZTM 1250 OPTIONAL FILL INDICATOR 970145 FIGURE 14 ...

Page 54: ...52 ZTM 1250 ZTM 1250 ZTM 1250 ZTM 1250 ZTM 1250 HYDROGEAR PUMP FIGURE 15 ...

Page 56: ...54 ZTM 1250 ZTM 1250 ZTM 1250 ZTM 1250 ZTM 1250 BRAKE ASSEMBLY FIGURE 16 ...