Summary of Contents for 100001

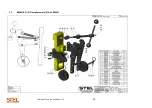

Page 15: ...Specialised Tools and Equipment Ltd 15 7 2 BRDM18 FUEL Clamp Assembly Pt No 100024 ...

Page 17: ...Specialised Tools and Equipment Ltd 17 ...

Page 19: ...Specialised Tools and Equipment Ltd 19 ...

Page 20: ...Specialised Tools and Equipment Ltd 20 ...

Page 21: ...Specialised Tools and Equipment Ltd 21 ...

Page 24: ...Specialised Tools and Equipment Ltd 24 NOTES ...