Stellar

®

TM7120 TireMan Owner’s Manual | Page 5

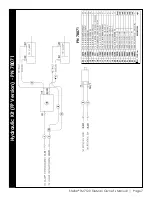

Hydraulic Installation

Never modify or alter any of the equipment, whether mechanical, electrical, or hydraulic,

without Stellar Industries’ approval.

Do not touch or grab any hoses that could be under pressure. Release

system pressure before attempting to make adjustments or repairs.

Do not attempt service or repair when PTO is engaged.

Disassemble and assemble hydraulic components on a clean surface.

Clean all metal parts in a nonflammable cleaning fluid. Then lubricate all components to

aid in assembly.

Hydraulic fluid expands when heated. This raises the pressure in an

unventilated tank. Release the tank pressure before removing the cap completely. Failure

to do so may cause the oil to shoot out of the tank very rapidly and cause severe burns.

Do not rely on the hydraulic fluid to support the boom or crane. If

hydraulic fluid escapes, the boom or crane can fall immediately. Make sure the ground or

blocking is supporting the boom before performing any maintenance or repair.

Contaminants in a hydraulic system affect operation and will result in

serious damage to the system components. Dirty hydraulic systems are a major cause of

component failures.

If evidence of foreign particles is found in the hydraulic system, flush the system.

When installing metal hydraulic tubes, tighten all fittings finger tight. Then , in order, tighten

the fittings at the rigid end, the adjustable end, and the mounting brackets. After tubes

are mounted, install the hoses. Connect both ends of the hose with all fittings finger tight.

Position the hose so it does not rub the machine or another hose and has a minimum of

bending and twisting. Tighten fittings in both couplings.

Due to manufacturing methods, there is a natural curvature to a hydralic hose. The hose

should be installed so any bend is with this curvature.

WARNING

WARNING

WARNING

NOTICE

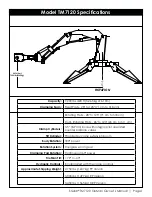

Summary of Contents for TireMan 7120

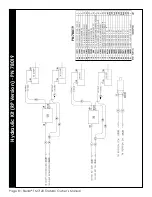

Page 11: ...Stellar TM7120 TireMan Owner s Manual Page 7 Hydraulic Kit FP Version PN 78071 PN 78071 ...

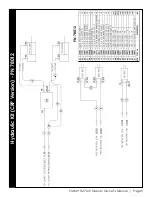

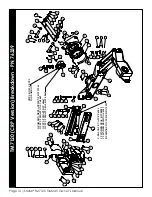

Page 12: ...Page 8 Stellar TM7120 TireMan Owner s Manual Hydraulic Kit RP Version PN 78019 PN 78019 ...

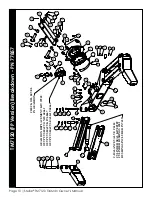

Page 13: ...Stellar TM7120 TireMan Owner s Manual Page 9 Hydraulic Kit CRP Version PN 78012 PN 78012 ...

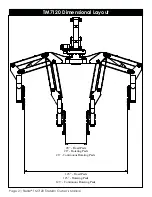

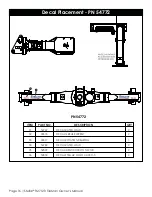

Page 21: ...Stellar TM7120 TireMan Owner s Manual Page 17 ...

Page 22: ...Subject to Change without Notification 2016 Stellar Industries Inc ...