20

Maintenance

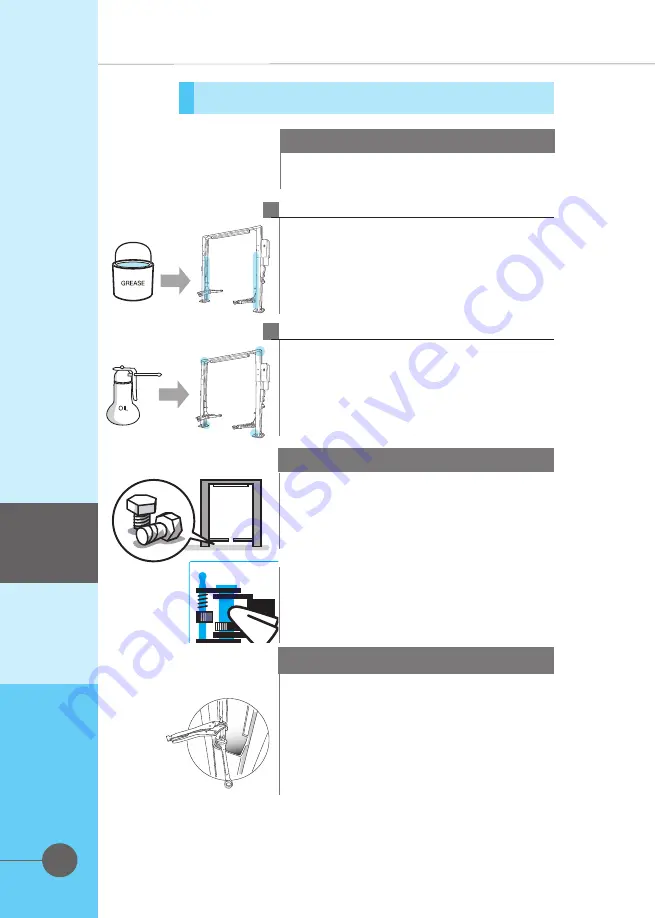

■ Lubrication

■ Cleanliness

▶At 2-or 3-month intervals, depending on

service usage.

▶Apply molybdenum disulphide grease liberally to

the carriage guides and the guide runners inside

the posts.

Molybdenum disulphide grease

1

▶

Check every day that the hoist is clean and

that the work area is clean and free from

debris or obstructions.

▶

Clean safety devices at 2-or-3-month intervals,

depending on service usage.

- Clean the arm lock gears and surroundings,

lubricate the gear teeth and the release

mechanisms. Clean the safety lock pawls, and

lubricate the axles.

■ Synchronization Cable Adjustment

▶

Check that both carriages are fully parked on the

base of the hoist at the bottom position. Raise the

hoist

without load and listen to the audible clicks of the 2

lock pawls. The synchronization of the

2 carriages is correct when both lock pawls click

simultaneously. Adjust the length of the 2 cables as

shown to fulfill this.

▶Lubricate with oil the upper and lower cable

rollers and axles.

Lubricating oil

2

Maintenance