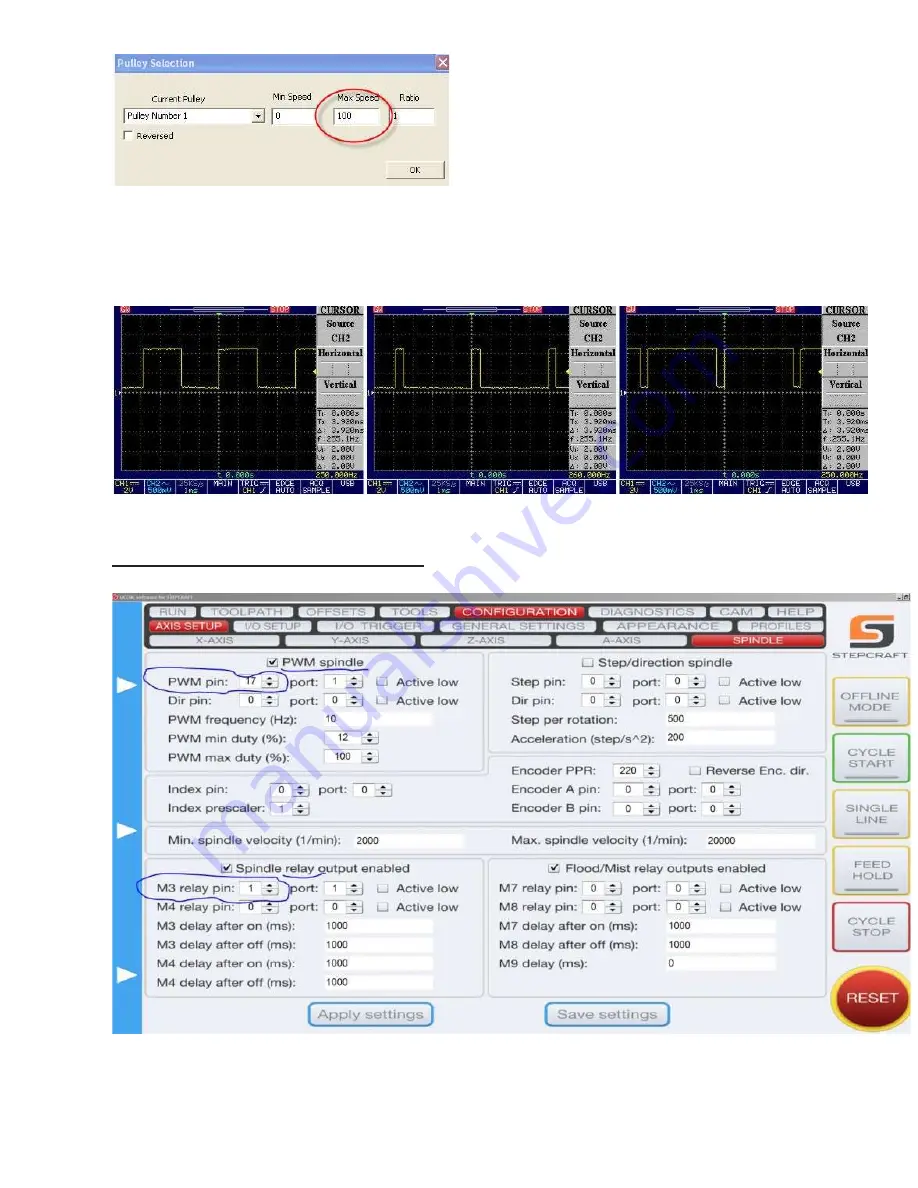

In the “Config” —> “Spindle Pullies” selection, enter “0” for Min Speed and “100” for Max Speed and a Ratio of “1”. This will then equate the spindle speed

setting for laser power with a one to one ratio. Full power is 100 and off is 0 (or better to use M5).

To control this new PWM output in G Code, simply add an “SXXX” command to the normal spindle M Code of M3 or M4 where the “XXX” is the power of

the laser. Some examples of the code are:

M3 S100 – Laser ON at full power

•

M3 S90 – Laser ON at 90% power

•

M3 S50 – Laser ON at 50% power

•

The image below shows different duty cycles for 50%, 10% and 90% respectively.

UCCNC Setup (if not using Mach 3)

Many people are using the UC100 and the UCCNC software to run their machine. Here is the quick guide to setting up the machine.

You will need to go into the “configuration” -> “axis setup” -> “spindle” tab. This is the screen that you will use to set the laser up as a “spindle”.

In the “Configuration -> I/O Setup” page, make sure to set the “Laser Pin” like below:

Quick Notes Page 4