Hold the housing so that it is in contact with the bottom of the joist. Attach the housing with four (4) screws to the joist through

the holes in each mounting flange.

1. MOUNT HOUSING TO JOIST OR I-JOIST.

HANGER

BAR

NAIL

2. MOUNT WITH HANGER BARS

2a. Sliding hanger bars have been provided, which allow the housing to be positioned accurately anywhere between the

framing. The bars span up to 24 in. and can be used on all types of framing: I-joist, standard joist, and truss construction.

Slide hanger bars onto housing and adjust as needed to fit between framing.

2b. Extend the hanger bars to the width of the framing. Position the ventilator with the hanger bar tabs wrapped around the

bottom edge of the framing, holding the ventilator in place.

Secure hanger bars to framing using one screw on each end of hanger bar.

Select a proper hole and secure the hanger bars together using flange screws.

OPERATION

TYPES OF TYPICAL INSTALLATIONS

1. Do not use in a cooking area.

2. Two ways to connect ductwork to a factory-shipped unit.

ASSEMBLY INSTRUCTIONS

1. Housing mounted to I-joists (Start at “ASSEMBLY INSTRUCTIONS 1”)

2. Housing mounted to joists (Start at “ASSEMBLY INSTRUCTIONS 1” )

3. Housing mounted to truss (Start at step “ASSEMBLY INSTRUCTIONS 2”)

SCREW

2

ROOF CAP*

(with built-in

damper)

ROUND

DUCT*

WALL CAP*

(with built-in

damper)

*

Purchase

separately

POWER

CABLE*

INSULATION*

(Place around and

over Fan Housing.)

Seal gaps

around

Housing.

FAN

HOUSING

ROUND

ELBOW(S) *

Seal duct

joints with

tape.

Keep duct

runs short

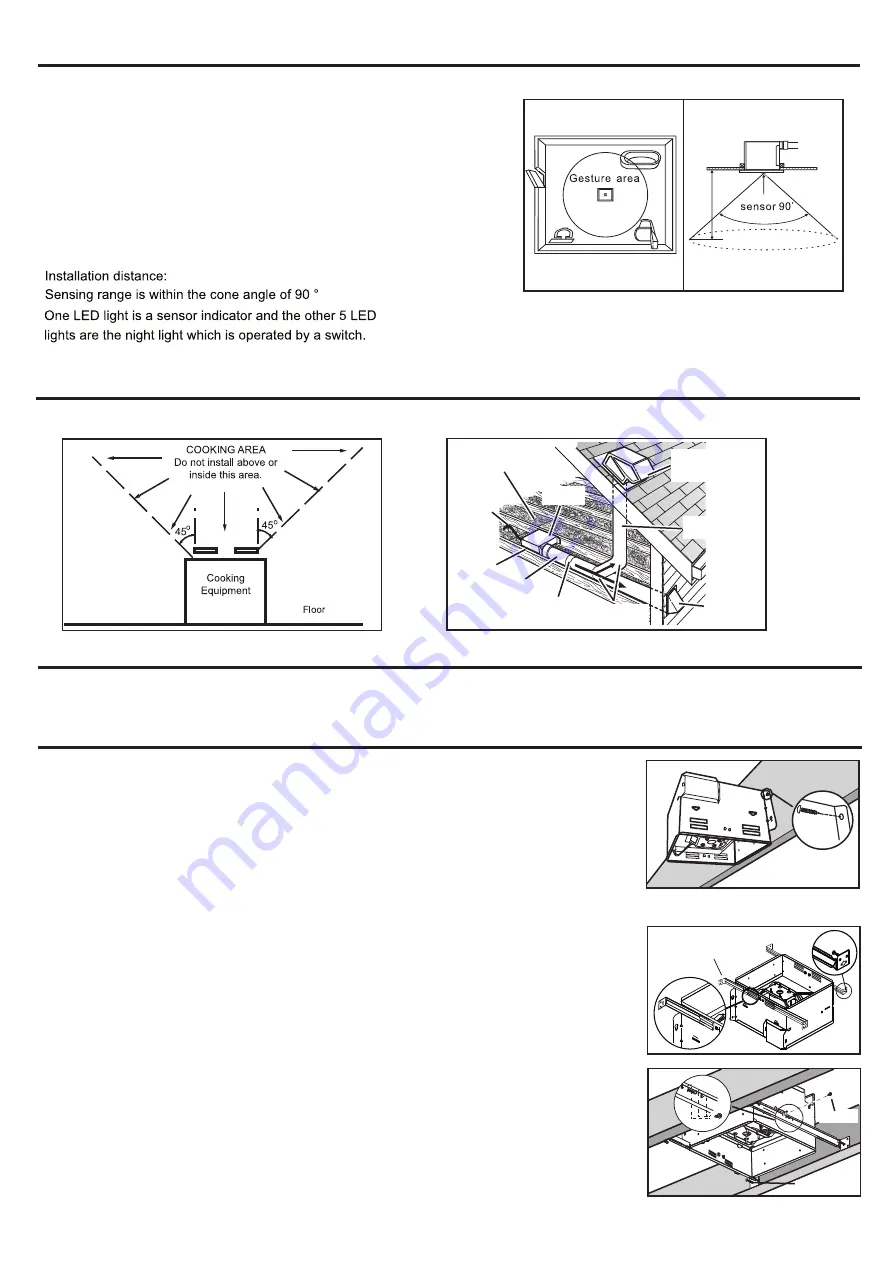

The fan, motion sensor and LED light can be operated

separarely.Sensing distance will be impacted of the body’s own

situation (for example, the thinner people wearing the more remote

sensing distance). Turn on the switch sensor system begins working,

the fan run continuously at a pre-set lower level. When enter the

gesture area fan begins working, indicator light begins flashing. When

persons leave, indicator light turn down, the fan remains working until

the delay time has passed, and then the fan transferred to the low-

speed (you set) operation.

7 to 9 feet

7 to 9 feet.

For model SED110M

PLAN THE INSTALLATION