17

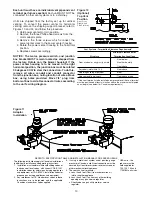

GAS PIPING

To avoid equipment damage or possible personal injury, do not connect gas piping to

this unit until a supply line pressure/leak test has been completed. Connecting the unit before

completing the pressure/leak test may damage the unit gas valve and result in a fire hazard.

Do not rely on a shut off valve to isolate the unit while conducting gas pressure/leak tests. These valves

may not be completely shut off, exposing the unit gas valve to excessive pressure and damage.

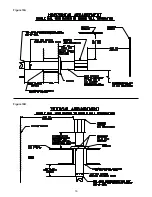

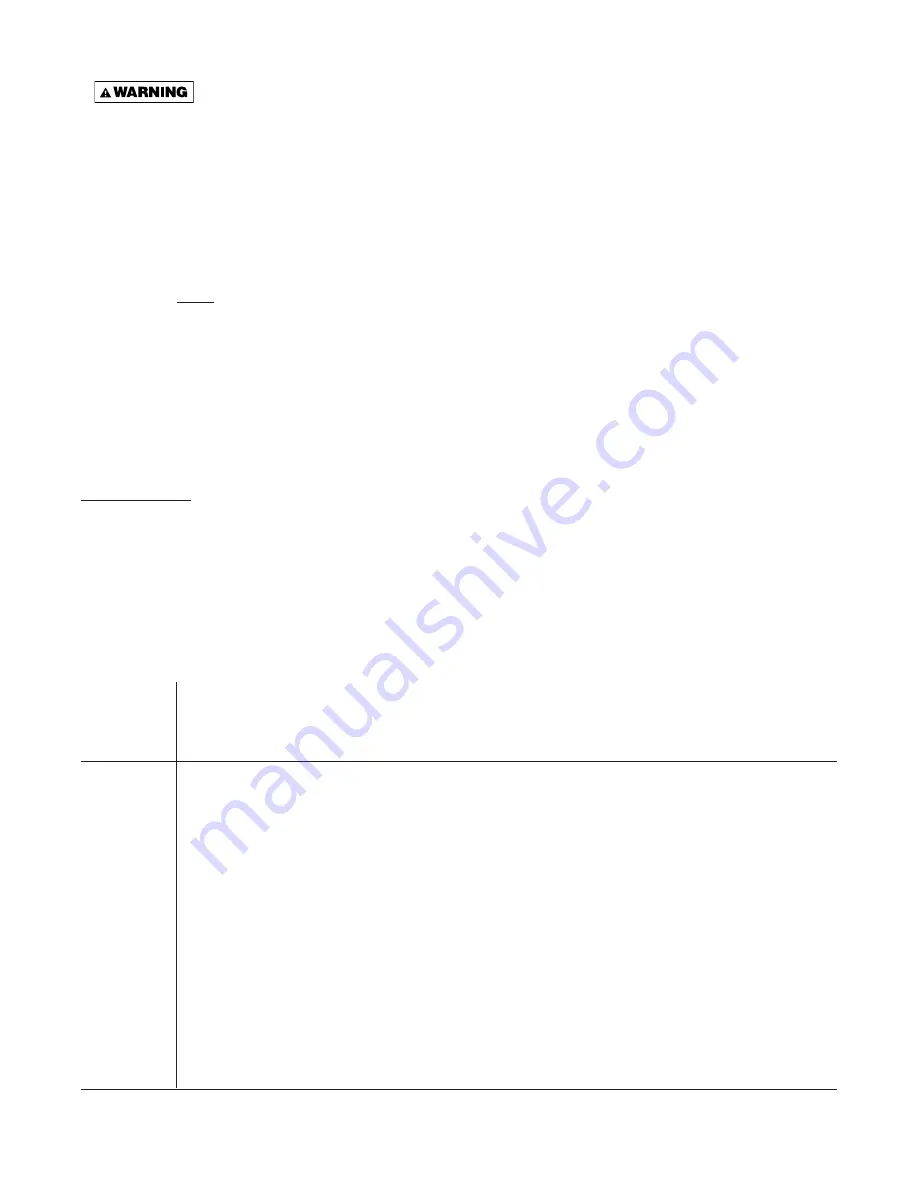

PIPE SIZING

To provide adequate gas pressure at the gas duct

furnace, size the gas piping as follows:

1.

Find the cu ft/hr by using the following formula:

Input

Cu ft/hr =

Btu

2.

Refer to Table 5. Match “Pipe Run in Feet” with

appropriate “Gas Input - Cu Ft/Hr” figure. This

figure can then be matched to the pipe size at the

end of the column.

Example: It is determined that a 67 foot (20.4m) run of gas

pipe is required to connect a 200 MBTU gas duct furnace

to a 1,000 Btu/cu. ft (0.29 kW) natural gas supply.

200,000 Btu/hr

= 200 Cu ft/hr

1,000 Btu/cu ft

Using Table 5, a 1 inch nominal diameter pipe is needed.

NOTICE: See General Safety Information section

for english/SI (metric) unit conversion factors.

Nominal

Iron

Pipe Size

Internal

Dia.

Maximum Capacity of Pipe in Cubic Feet of Gas per Hour for Gas Pressures of 0.5 psig (3.5 kPa) or Less,

and a Pressure Drop of 0.5 Inch Water Column (124.4 Pa)

(Based on a 0.60 Specific Gravity Gas)

Length of Pipe, ft. (Meters)

GAS PIPE SIZE

in.

in.

10

20

30

40

50

60

70

80

90

100

125

150

175

200

(mm)

(3.0)

(6.1)

(9.1)

(12.2)

(15.2) (18.3)

(21.3)

(24.4)

(27.4)

(30.5)

(38.1)

(45.7)

(53.3)

(61.0)

1/2

0.622

175

120

97

82

73

66

61

57

53

50

44

40

37

35

(16)

(4.96)

(3.40)

(2.75)

(2.32)

(2.07) (1.87)

(1.73)

(1.61)

(1.50)

(1.42)

(1.25)

(1.13)

(1.05)

(0.99)

3/4

0.824

360

250

200

170

151

138

125

118

110

103

93

84

77

72

(21)

(10.2)

(7.08)

(5.66)

(4.81)

(4.28) (3.91)

(3.54)

(3.34)

(3.11)

(2.92)

(2.63)

(2.38)

(2.18)

(2.04)

1

1.049

680

465

375

320

285

260

240

220

205

195

175

160

145

135

(27)

(19.3)

(13.2)

(10.6)

(9.06)

(8.07) (7.36)

(6.80)

(6.23)

(5.80)

(5.52)

(4.96)

(4.53)

(4.11)

(3.82)

1 1/4

1.380

1400

950

770

660

580

530

490

460

430

400

360

325

300

280

(35)

(39.6)

(26.9)

(21.8)

(18.7)

(16.4) (15.0)

(13.9)

(13.0)

(12.2)

(11.3)

(10.2)

(9.20)

(8.50)

(7.93)

1 1/2

1.610

2100

1460

1180

990

900

810

750

690

650

620

550

500

460

430

(41)

(59.5)

(41.3)

(33.4)

(28.0)

(25.5) (22.9)

(21.2)

(19.5)

(18.4)

(17.6)

(15.6)

(14.2)

(13.0)

(12.2)

2

2.067

3950

2750

2200

1900

1680

1520

1400

1300

1220

1150

1020

950

850

800

(53)

(112)

(77.9)

(62.3)

(53.8)

(47.6) (43.0)

(39.6)

(36.8)

(34.5)

(32.6)

(28.9)

(26.9)

(24.1)

(22.7)

2 1/2

2.469

6300

4350

3520

3000

2650

2400

2250

2050

1950

1850

1650

1500

1370

1280

(63)

(178)

(123)

(99.7)

(85.0)

(75.0) (68.0)

(63.7)

(58.0)

(55.2)

(52.4)

(46.7)

(42.5)

(38.8)

(36.2)

3

3.068

11000

7700

6250

5300

4750

4300

3900

3700

3450

3250

2950

2650

2450

2280

(78)

(311)

(218)

(177)

(150)

(135)

(122)

(110)

(105)

(97.7)

(92.0)

(83.5)

(75.0)

(69.4)

(64.6)

4

4.026

23000

15800

12800

10900

9700

8800

8100

7500

7200

6700

6000

5500

5000

4600

(102)

(651)

(447)

(362)

(309)

(275)

(249)

(229)

(212)

(204)

(190)

(170)

(156)

(142)

(130)

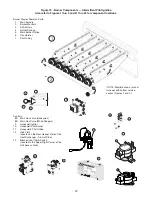

1. Determine the required Cu. Ft. / Hr. by dividing the rated heater input by 1000. 2. FOR NATURAL GAS: Select the pipe size directly

from the table. 3. FOR PROPANE GAS: Multiply the Cu. Ft. / Hr. value by 0.633; then use the table. 4. Refer to the metric conversion

factors listed in General Safety section for SI unit measurements/conversions.

Table 5

NOTICE: If more than one gas duct furnace is to be

served by the same piping arrangement, the total cu

ft/hr input and length of pipe must be considered.

NOTICE: If the gas duct furnace is to be fired with

LP gas, see below and consult the local LP gas

dealer for pipe size information.

NOTICE: HEATER INSTALLATION FOR USE WITH

PROPANE (BOTTLED) GAS MUST BE MADE BY A

QUALIFIED L.P. GAS DEALER OR INSTALLER. HE

WILL INSURE THAT PROPER JOINT COMPOUNDS

ARE USED FOR MAKING PIPE CONNECTIONS; THAT

AIR IS PURGED FROM LINES; THAT A THOROUGH

TEST IS MADE FOR LEAKS BEFORE OPERATING

HEATER; AND THAT IT IS PROPERLY CONNECTED

TO PROPANE GAS SUPPLY SYSTEM.

Before any connection is made to an existing line

supplying other gas appliances, contact the local gas

company to make certain that the existing line is of

adequate size to handle the combined load.

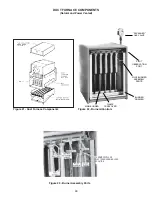

Summary of Contents for NATURAL INDOOR GAS-FIRED DUCT FURNACE

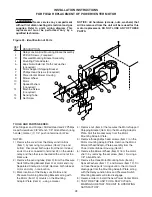

Page 14: ...14 Figure 12A Figure 12B...

Page 15: ...15 Figure 13A Figure 13B...

Page 34: ...34 NOTES...

Page 36: ......