14

15

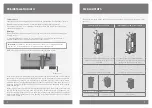

Illustration

solution

cause

Indication

1. Increase the air to soap

ratio.

Liquid rather than

foam is being

dispensed out of

the nozzle

Foam not dispensing

2. Verify that the filter is

clean.

3. Replace compressor

(supplied with pump). For

part numbers see spare

parts list.

Use remote to decrease soap

volume by pressing the "-

soap" key.

Foam dosage is too

large

Foam is dispensing

Use remote to increase soap

volume by pressing the "+

soap" key.

Foam dosage is too

small

Use remote to decrease the

amount of air in the foam by

pressing the "- Air" Key.

Foam is too dense

Use remote to increase the

amount of air in the foam by

pressing the " + Air" key.

Foam is too

liquefied

tRoubleshootIng

lImIted waRRantY

Y. Stern Engineering Ltd. warrants that its electronic products will be free of defects in

material and workmanship during normal use for two years from the date the product is

purchased.

if a defect is found in normal use, Y. Stern Engineering Ltd. will, at its discretion, repair,

provide a replacement part or product, or make appropriate adjustments. damage caused

by accident, misuse, or abuse is not covered by this warranty. improper care and cleaning

will void the warranty. proof of purchase (original sales receipt) must be provided to Stern

Engineering Ltd. with all warranty claims.

Stern Engineering Ltd is not responsible for labor charges, installation, or other incidental

or consequential costs other than those noted above. in no event shall the liability of

Stern Engineering Ltd. exceed the purchase price of the product.

if you believe that you have a warranty claim, contact your Stern distributor, dealer or

plumbing Contractor. please be sure to provide all pertinent information regarding your

claim, including a complete description of the problem, the product, model number,

the date the product was purchased, from whom the product was purchased and the

installation date. Also include your original invoice.

Y. STErn EnGinEErinG And/Or SELLEr diSCLAiM AnY LiABiLiTY FOr SpECiAL, inCidEnTAL

Or COnSEQUEnTiAL dAMAGES. This warranty excludes product damage due to installation

error, incorrect maintenance, wear and tear, battery, product abuse, or product misuse,

whether performed by a contractor, service company, or the consumer. This warranty does

not cover product damage caused by the following:

- incorrect installation.

- inversions of supply pipes.

- pressures or temperatures exceeding recommended limits.

- improper manipulation, tampering, bad or lapsed maintenance.

- Foreign bodies, dirt or scale introduced by the water supply or soap tank.

- Use of the soap outside of viscosity specifications.

- Alteration of the original soap/foam dispenser components (including pipes).

Summary of Contents for 280200

Page 10: ...16 17 ...