Maintenance procedures

Operation & maintenance instructions (Version H)

66

SKY-200/250

7.

Lower the cylinder by opening the emergency lowering device of the valve or by

pressing the corresponding switch S1 - S4 in the control box.

8.

Disassemble the two locking plates at both ends of the axle. Take care not to mix up

the slide rings.

9.

When the cylinder is lowered under the track, disconnect the pull bars by removing

the axle that connects the cylinder and the pull bars. Use a bronze punch and a

hammer. Take care to secure the pull bars during removal of the axle.

This can be done by tying them to the track. Do not completely punch the axle to one

side but only far enough to disconnect the pull bar on that side. Then the bearing

bush on the other side will come out. Next, punch the axle back, far enough to

disconnect the other pull bar.

10.

In case of a flush mounted lift, cover the pit underneath the cylinder for example with

a pallet.

11.

Lower the cylinder (as described before) completely and let it rest onto the pallet or

floor. Make sure there is no hydraulic pressure in the system and disconnect the

hydraulic hose.

12.

Remove the locking plates.

13.

Remove the axle at the piston side using the supplied auxiliary bushing. This

bushing provides a temporary connection of locking pawls and cylinder.

14.

Remove the cylinder assembly completely.

15.

Disassemble the locking mechanism from the old cylinder and mount it on the

replacement cylinder.

Mount the replacement cylinder in reverse order, taking notice of the next remarks:

• Take care to mount the right sliding rings at the right places.

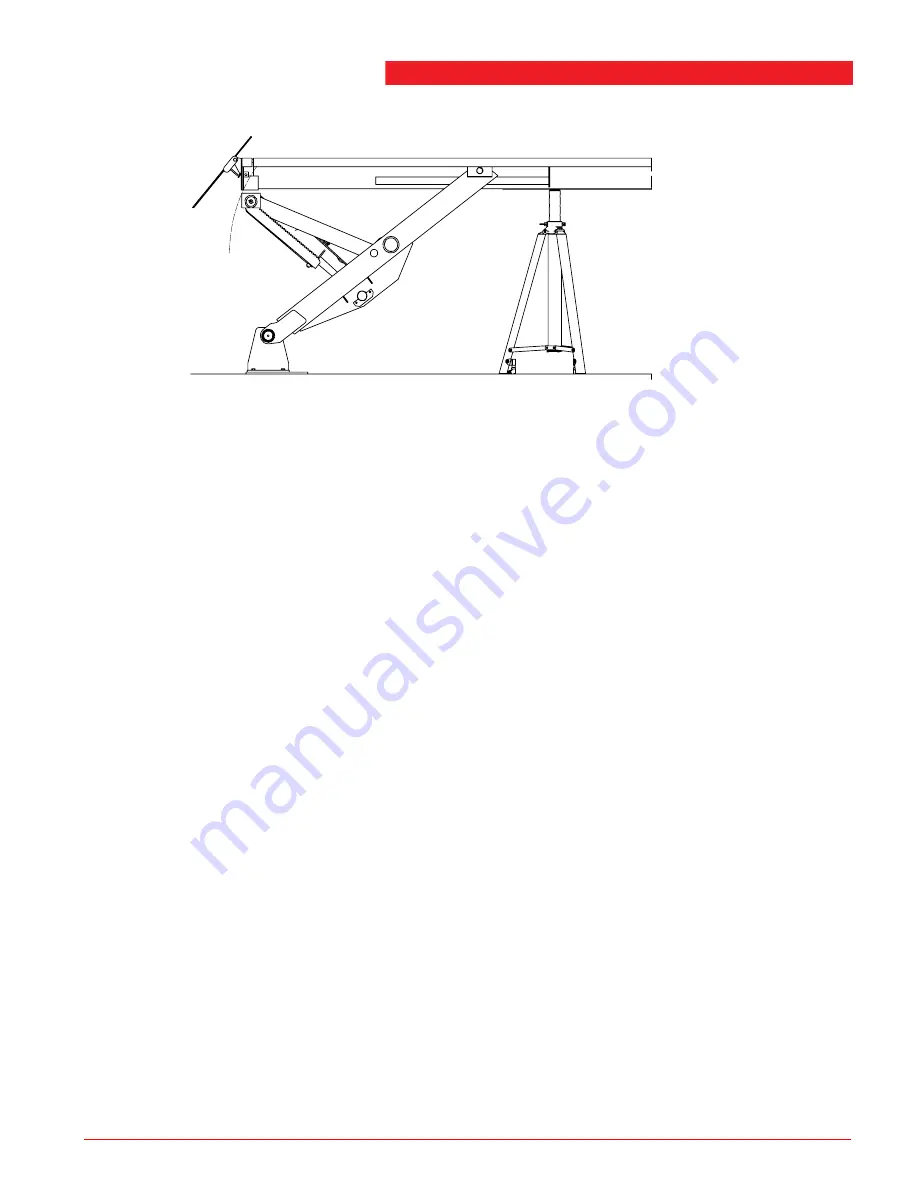

Figure 7.3

Disconnecting the blocks from the tracks

Summary of Contents for SKY-200

Page 152: ...Operation maintenance instructions Version H 152 SKY 200 250 ...

Page 153: ......